Gravity Extenders Benefit Utility Installations

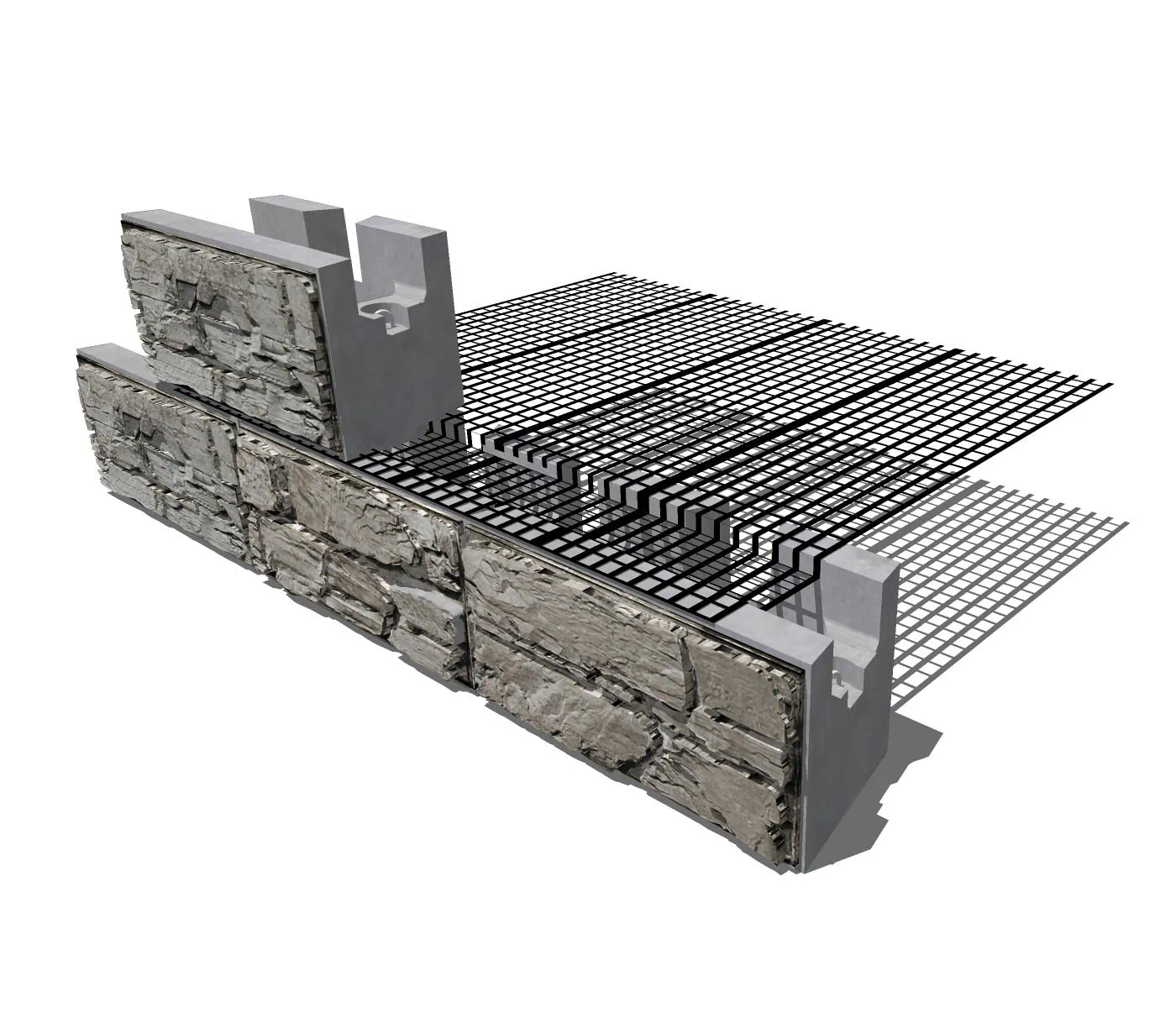

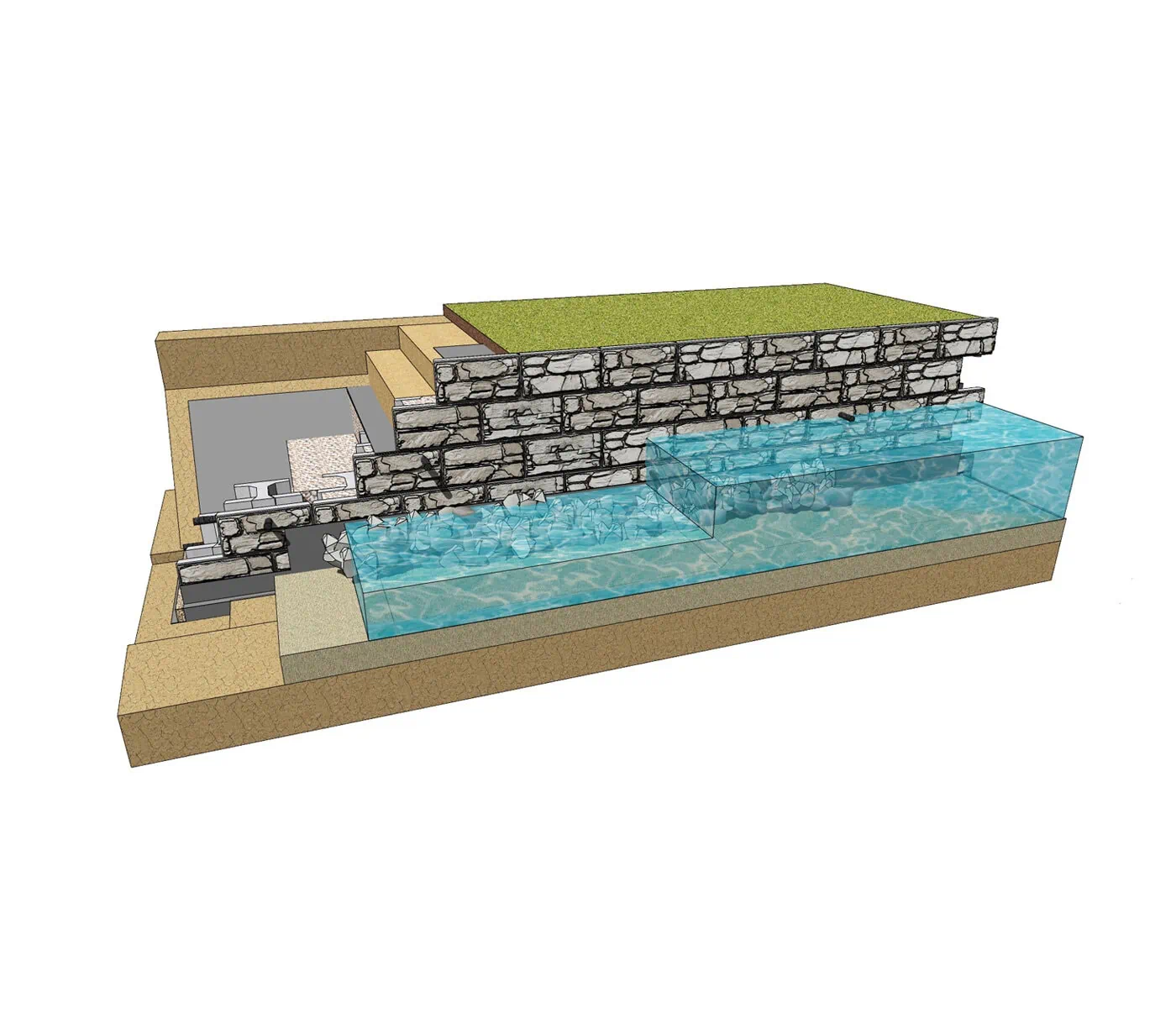

Designing and installing retaining walls for residential or commercial developments involve many key considerations, including the installation of behind-the-wall services. It has progressively become more common for wall designers, contractors, and engineers to refrain from choosing geogrid wall solutions projects with utilities and structures behind the blocks. That’s because industry experts know that it’s easier and faster to install and access utilities and piping behind gravity retaining walls, especially with the help of gravity extenders.

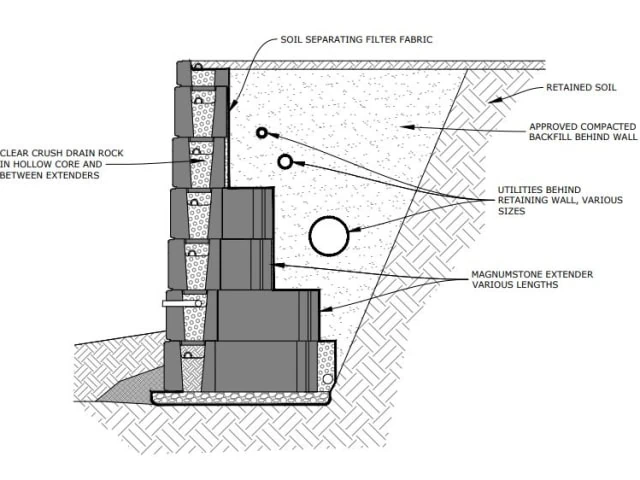

Big block retaining wall systems like MagnumStone and its signature multi-length gravity extender units provide more flexibility and less obstacles for these vital services. By removing geogrid from the equation, there are less complications to contend with. From essential drainage pipes to infrastructure utilities and sewage lines, gravity retaining walls make it easier for engineers and contractors to plan and install these underground amenities directly behind the wall system.

Replace Geogrid Designs with Gravity Retaining Wall Extenders

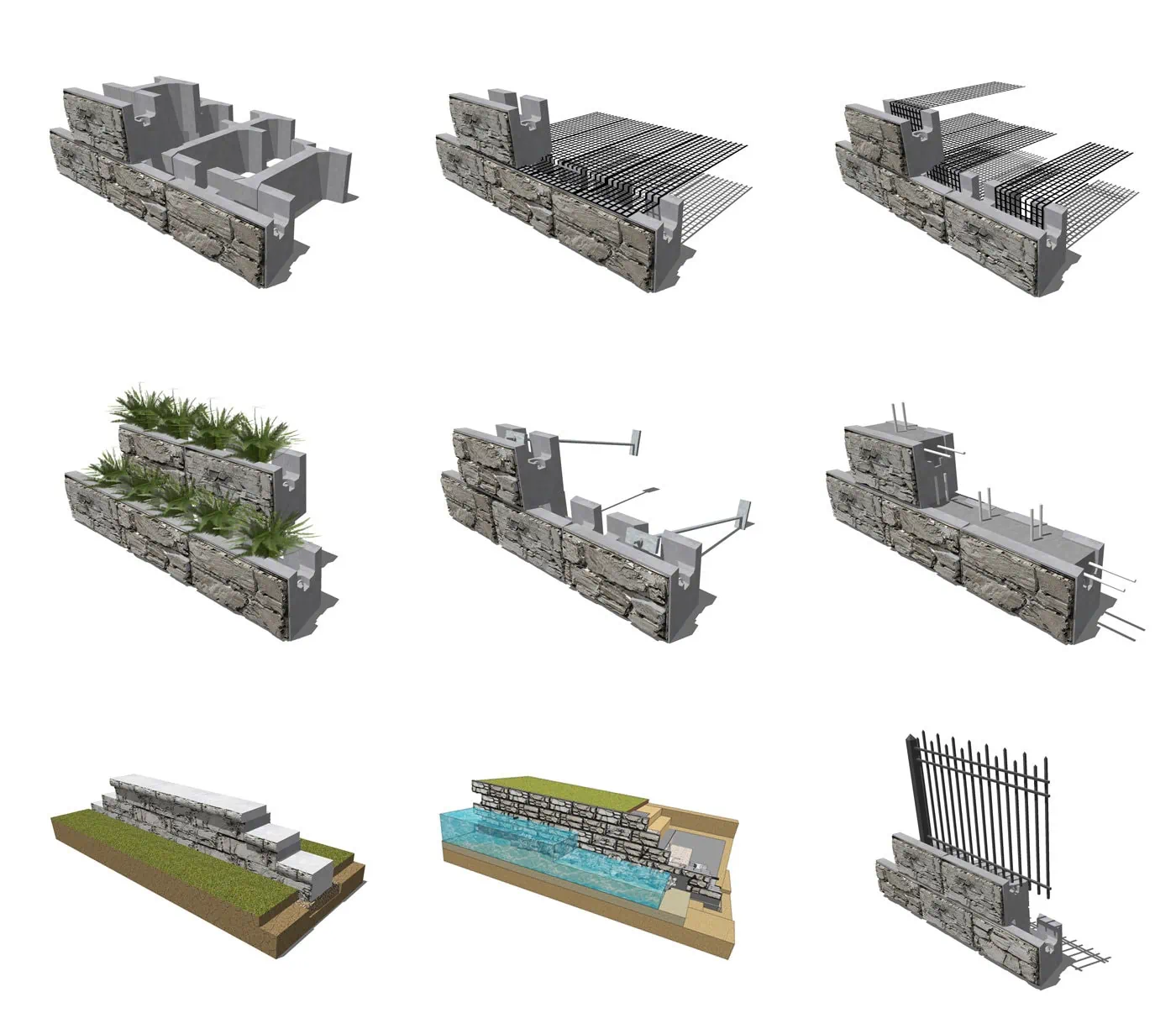

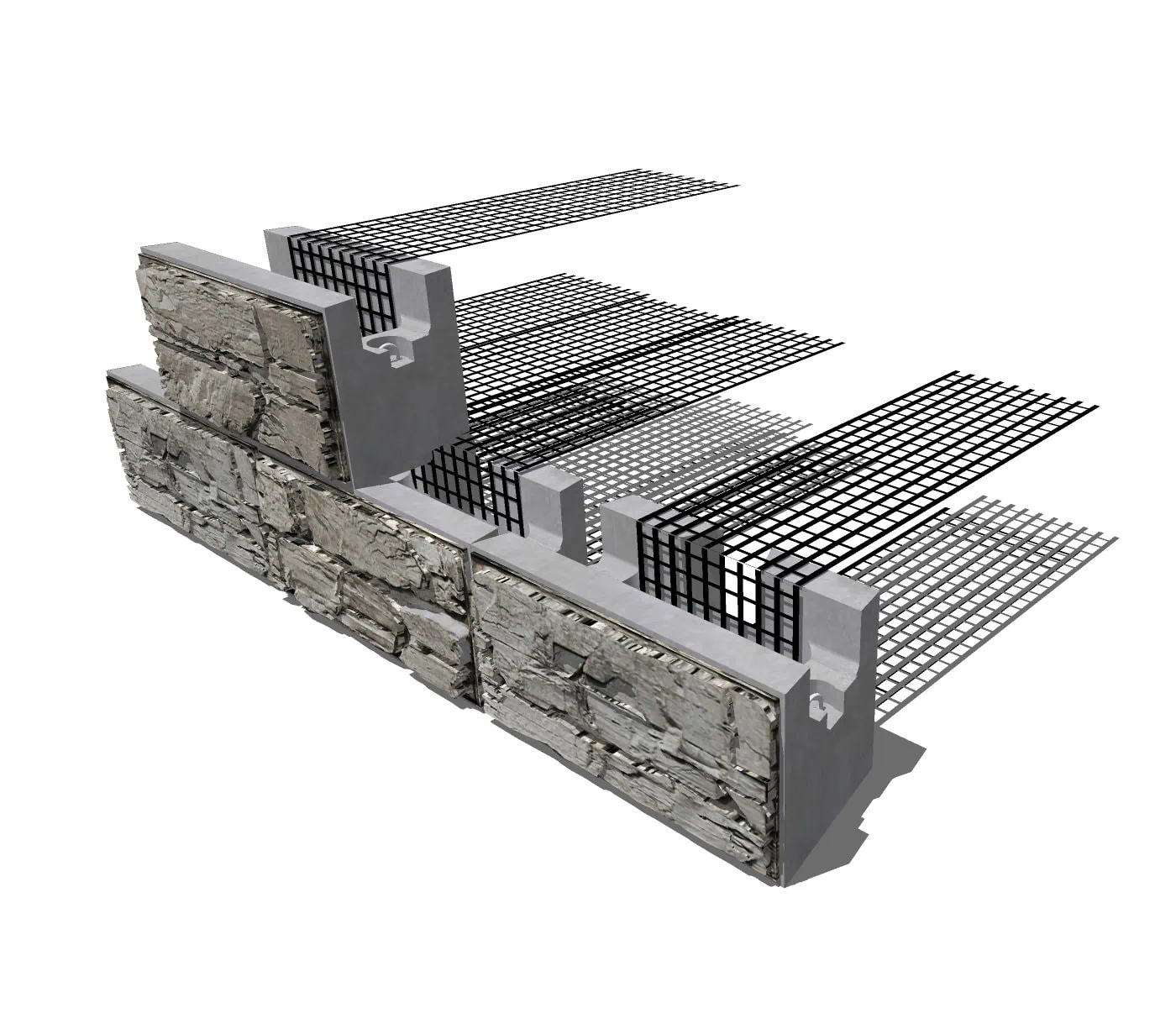

Gravity extender units of big block retaining walls are the key to successful transitions away from geogrid. MagnumStone’s short and long gravity extenders may be buried behind the scenes, but their remarkable impacts make them a game-changer for current and future retaining wall designs.

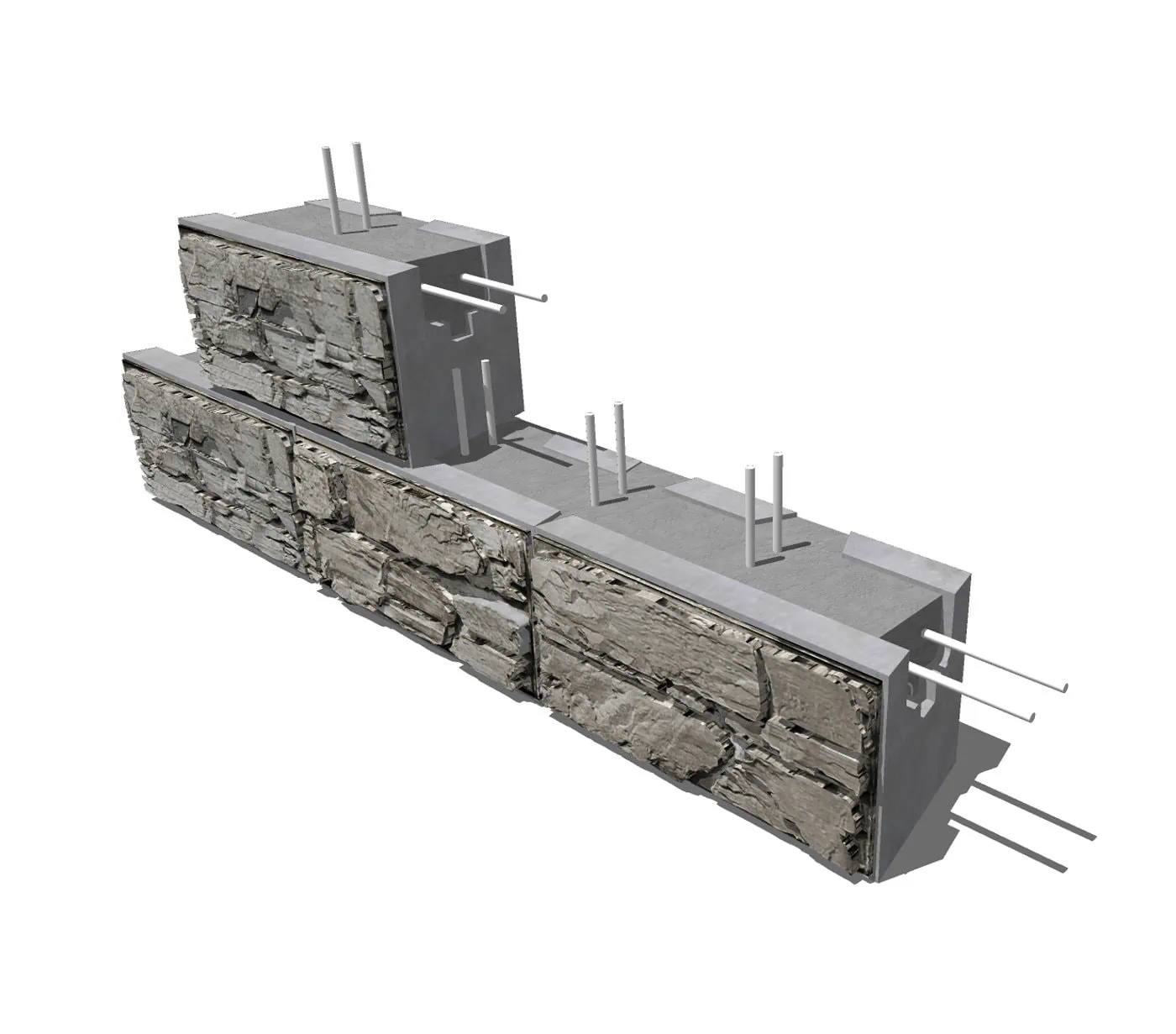

The extender units securely attach to MagnumStone’s standard wall blocks with an interlocking tongue-and-groove connection to increase mass and stability at the base of gravity walls. The total mass of the hollow core blocks and extenders allows gravity walls to be constructed taller by further strengthening the wall and effectively serving as an alternative solution to geogrid wall designs.

Faster Installations of Piping and Utility Lines

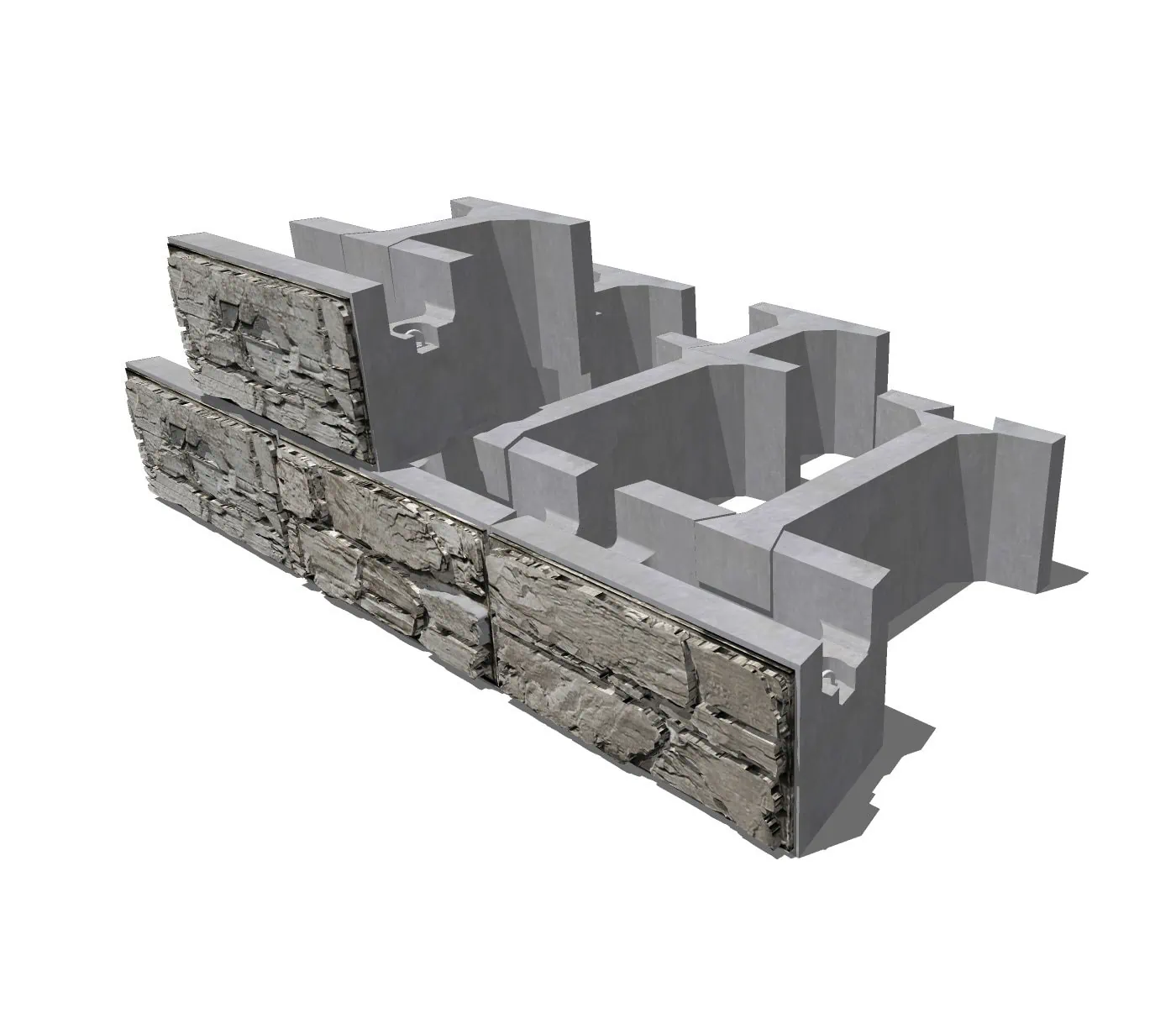

Naturally, installing gravity retaining walls is a quicker process than constructing geogrid walls. The usual process involves laying, measuring, cutting, and compacting approved backfill soils in multiple layers of geogrid material. But with gravity retaining walls, all you have to do is lift the blocks directly into place. It’s a major time-saver! This is particularly beneficial when geogrid must be cut to fit around structures like streetlights or guard rail posts from above the wall. The gravity extenders simply make it possible to build gravity retaining walls taller – and at a faster pace.

In terms of behind-the-wall services for these retaining wall designs, contractors prefer gravity wall designs because there are fewer complications for pipelayers and utility companies. With a reduced number of complications comes the ease of installation and quicker completed projects. Placing and securing geogrid around catch basins, utility lines, and sewage pipes must be diligently planned to ensure the materials maintain their strength and performance.

Alternatively, gravity walls and extenders require smaller teams and can cover more facing areas in less time. Why not expedite the construction of soil retention walls by streamlining the installation process so you can move on to your next project sooner?

Gravity Retaining Walls Simplify Behind-the-Wall Access

For maintenance purposes, utilities behind retaining walls are more accessible without layers of geogrid impeding the reach of workers. In case repairs are needed for sewage, power lines, or drainpipes, backfill excavation for geogrid retaining walls must be carefully executed in order to carefully avoid damaging any geogrid layers.

Comparatively, the same situation for services located behind gravity retaining walls is relatively easy. In the event of an emergency, time-saving excavations of gravity wall backfill can be completed quicker to accelerate repairs and minimize issues. Less time spent excavating is a massive benefit of gravity extender units, which can lead to significant cost savings and the potential for faster power restorations.

Recover More Space Above or In Front of Gravity Walls

A primary advantage of gravity wall extenders is less impactful excavation or cut-back areas, helping developers, contractors, and homeowners preserve more of their natural landscape. The gravity extender units offer a significant difference by requiring as low as a 40% base-to-height ratio for retaining wall excavation areas, whereas geogrid walls typically require 60%. This effectively offers more design flexibility to engineers and contractors when choosing where to place utilities, drainage, and piping.

When making efforts to install utilities as close as possible to property lines, MagnumStone’s extender units can also deliver more space below the wall. By saving up to 20% of the wall’s excavation area compared to geogrid designs, gravity walls with extenders can ensure landowners get the most out of their property’s land usage without sacrificing durability or performance.

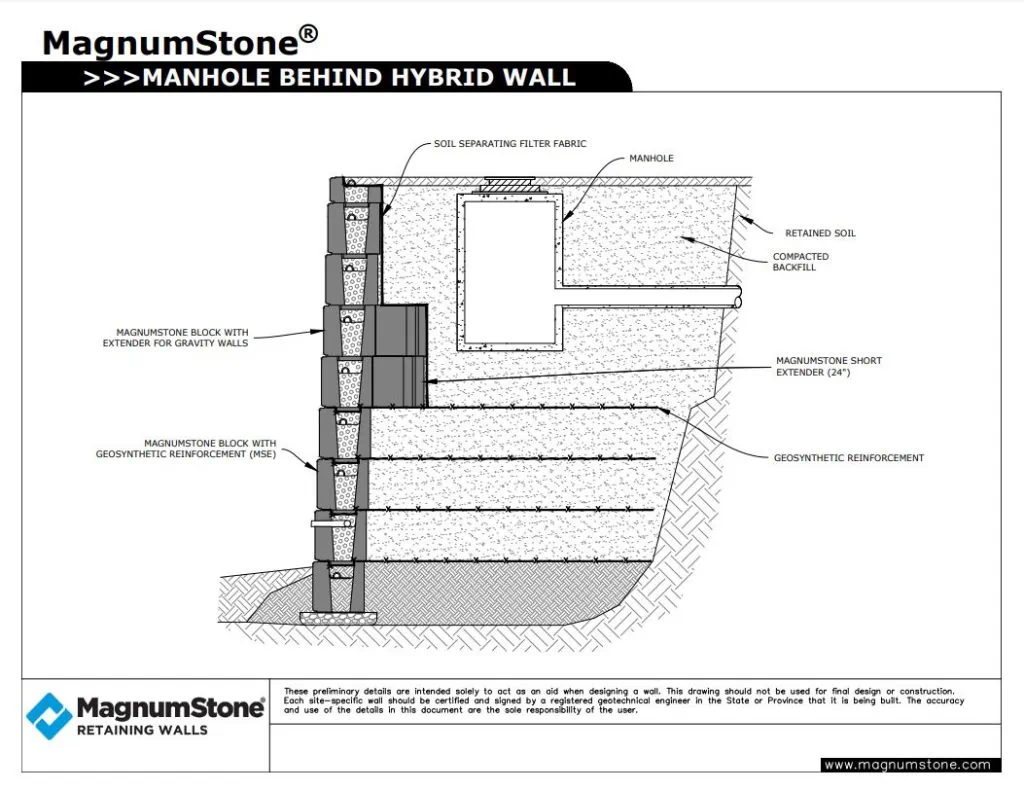

Build Hybrid Retaining Walls – The Best of Both Worlds

There’s also a unique third option that includes both gravity extenders and geogrid retaining walls. Hybrid retaining walls are gaining popularity by combining the best features of each. For hybrid retaining walls, the bottom courses are secured by geogrid, and the top courses are fortified by gravity extenders. This allows contractors and maintenance workers easier access to the surface of backfill areas, where utility pipes are typically installed.

Transitioning from geogrid to gravity designs mid-wall can comfortably be achieved. Common applications of these designs are when there are potential undermining issues for structures above the wall or access for utilities is needed without the disruption of geogrids within that excavation area.

Curious about the concept of hybrid retaining wall designs? This MagnumStone case study of a residential retaining wall project offers a great example of this application in action.

Learn more about the benefits of gravity retaining wall extenders, geogrid retaining walls, and hybrid retaining walls today. Contact your local MagnumStone experts for further insight, or begin designing your next project in minutes with our free, time-saving MagnumStone Retaining Wall Design & Analysis Software.

Photos: Cirtex, York Building Products, and Midwest Brick & Block