Infrastructure’s Precast Potential

It’s become common knowledge that aging worldwide infrastructure has seen rapid deterioration due to lack of investment and deferred maintenance. The natural lifecycle of past construction materials is expiring; therefore governments, engineers, architects, and contractors are looking for a wide range of proactive, everlasting approaches that streamline present and future infrastructure designs.

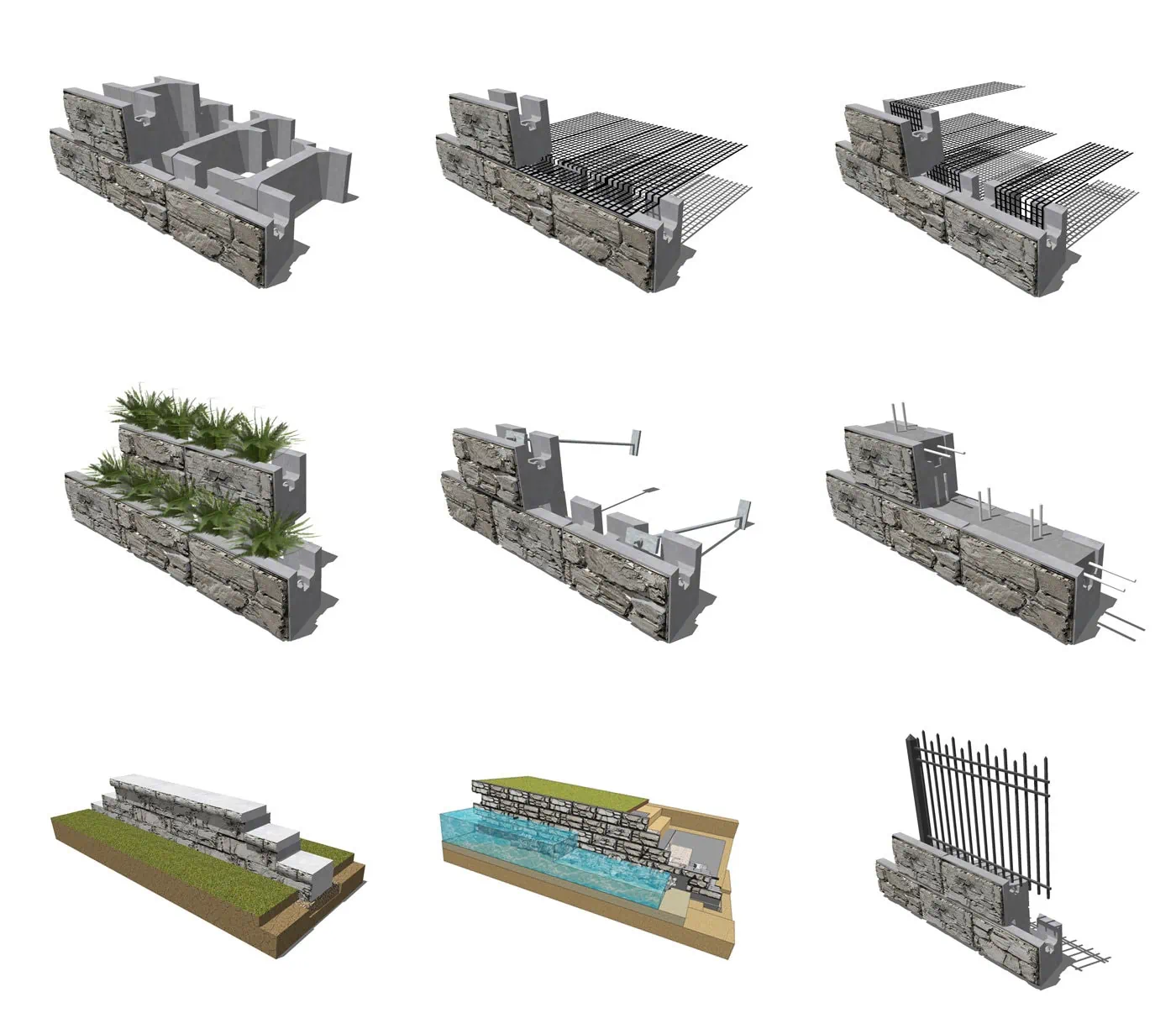

Fortunately, the established success of large precast retaining wall systems has made major impacts that expedite these projects with advanced, long-standing infrastructure solutions. The performance of multi-purpose wet-cast concrete retaining wall systems like MagnumStone provide cost-savings in terms of transportation and meeting project deadlines. With the versatility to easily install around light poles and utilities, it’s easy to see why these concrete blocks are such highly regarded materials.

Let’s examine what makes large retaining wall blocks ideal for infrastructure applications and how they excel to overcome today’s widespread construction challenges across the globe.

Everlasting Capabilities of Precast Concrete

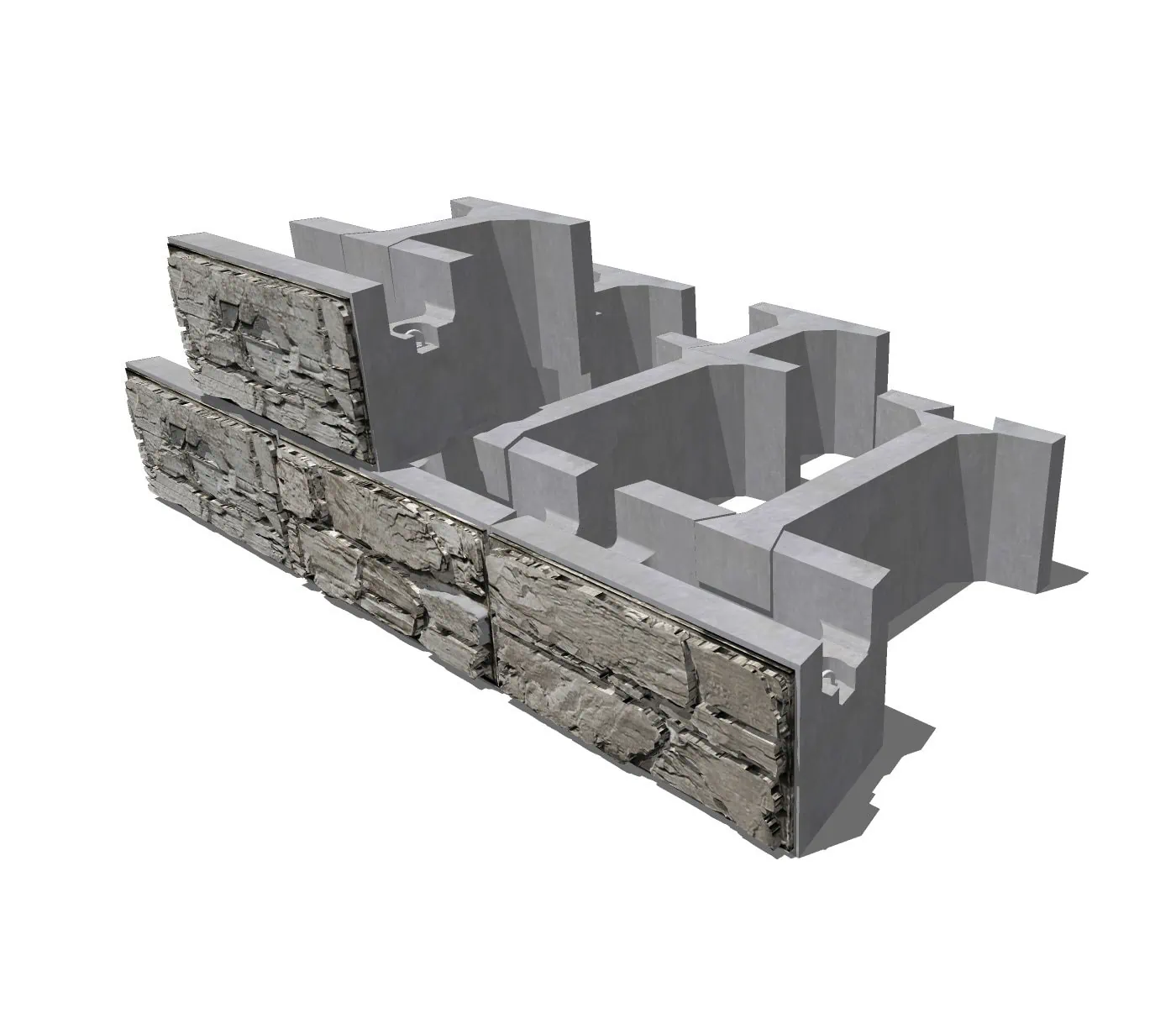

First, let’s connect the dots on why precast wet-cast concrete blocks are so effective for infrastructure projects. Strong, durable products are needed for these applications and modular block walls offer this in abundance. A key consideration for any retaining wall and infrastructure longevity is that water commonly leads to issues. The reality is that most projects are inevitably exposed to water in some form. Unlike many construction materials, precast blocks defend well against water.

The retaining wall blocks’ strength and resilience are derived from their production process. In fact, the controlled environment of wet-cast concrete manufacturing promotes high quality control measures. Precast blocks are renowned for weather-resistance thanks to their low-absorption composition. Since water is a primary enemy of retaining walls – and infrastructure in general – MagnumStone’s water-resistant blocks are a sound investment that remain secure for decades.

Quickly Repair, Proactively Mitigate Landslides

Countries around the world have become progressively prone to once-a-century storms that result in severe rainfall events and subsequent flooding or landslides. Infrastructure built decades ago were not designed or reinforced to deal with such common occurrences of these unpredictable natural disasters. Preventative measures are now being taken to repair old infrastructure and proactively design new projects with contemporary precast retaining wall solutions that help mitigate their effects.

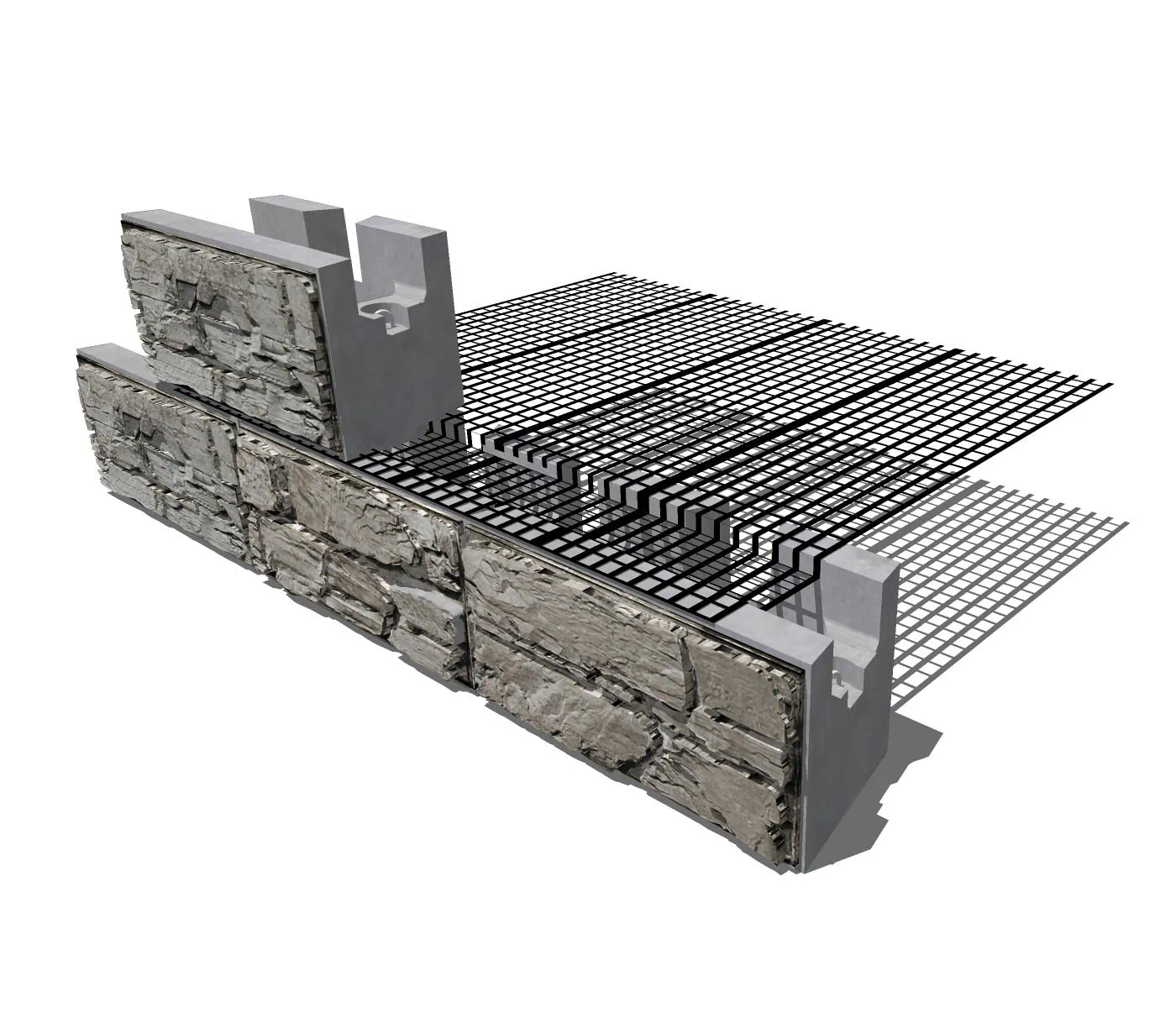

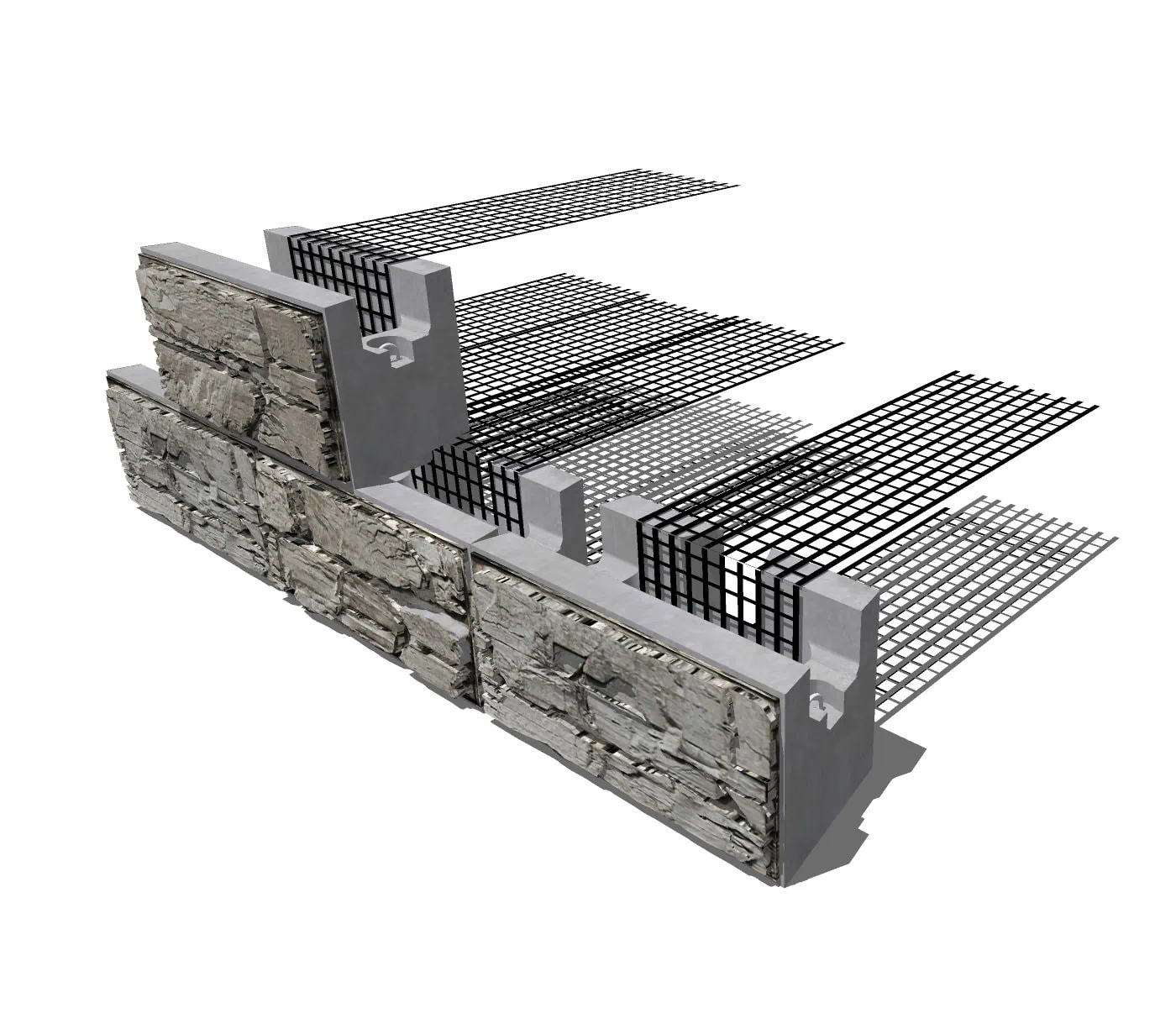

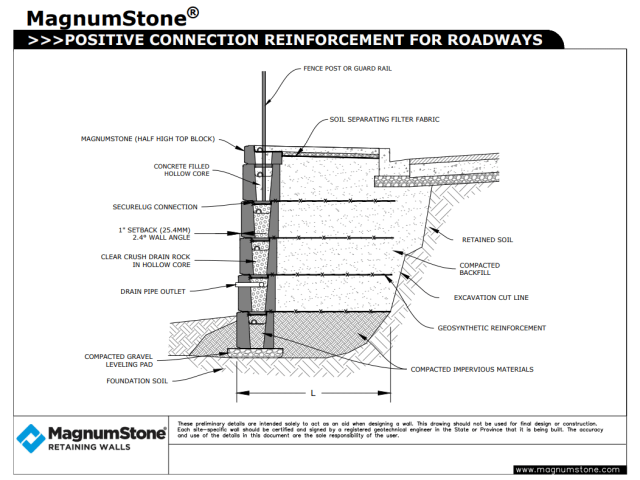

Vulnerable roads and highways, especially those leading to remote or mountainous locations, are being bolstered with precast retaining walls to safeguard economically important routes. Reinforced by positive connection geogrid designs, MagnumStone can achieve 100% geogrid coverage for key infrastructure and deliver supreme earth retention.

Secure Bridge Wing Wall Applications

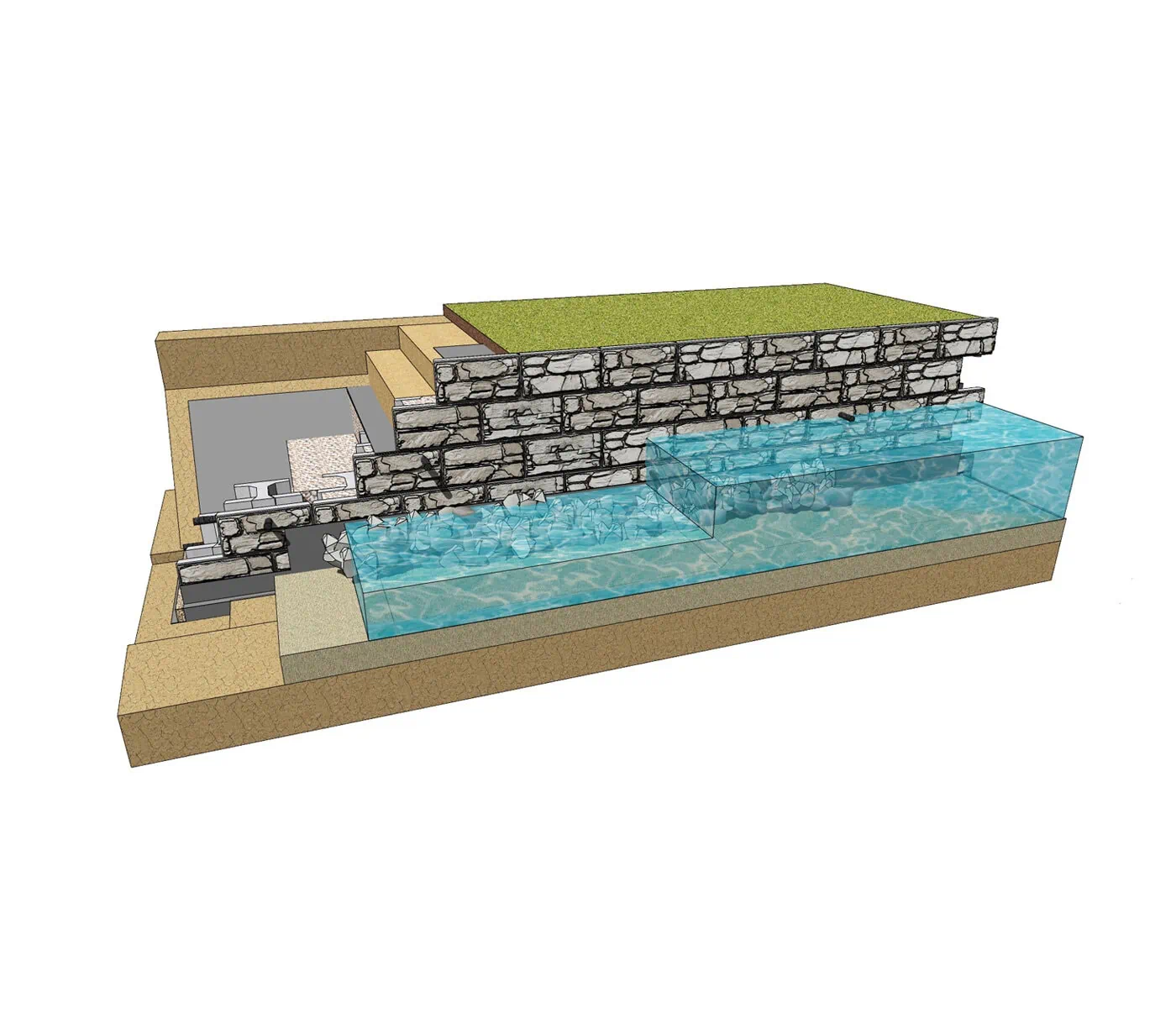

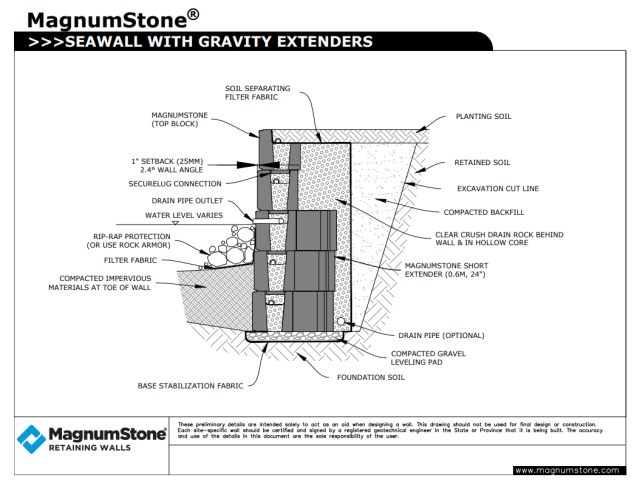

The weather-resistant nature of precast blocks helps them adapt to a wide array of applications and bridge structures are a prominent example. Heavy active loading of large vehicles combined with the presence of water necessitate secure, stable structures. MagnumStone retaining wall blocks offer proven bridge design solutions, to construct bridge headwalls along waterway embankments or wing walls submersed in varying water levels.

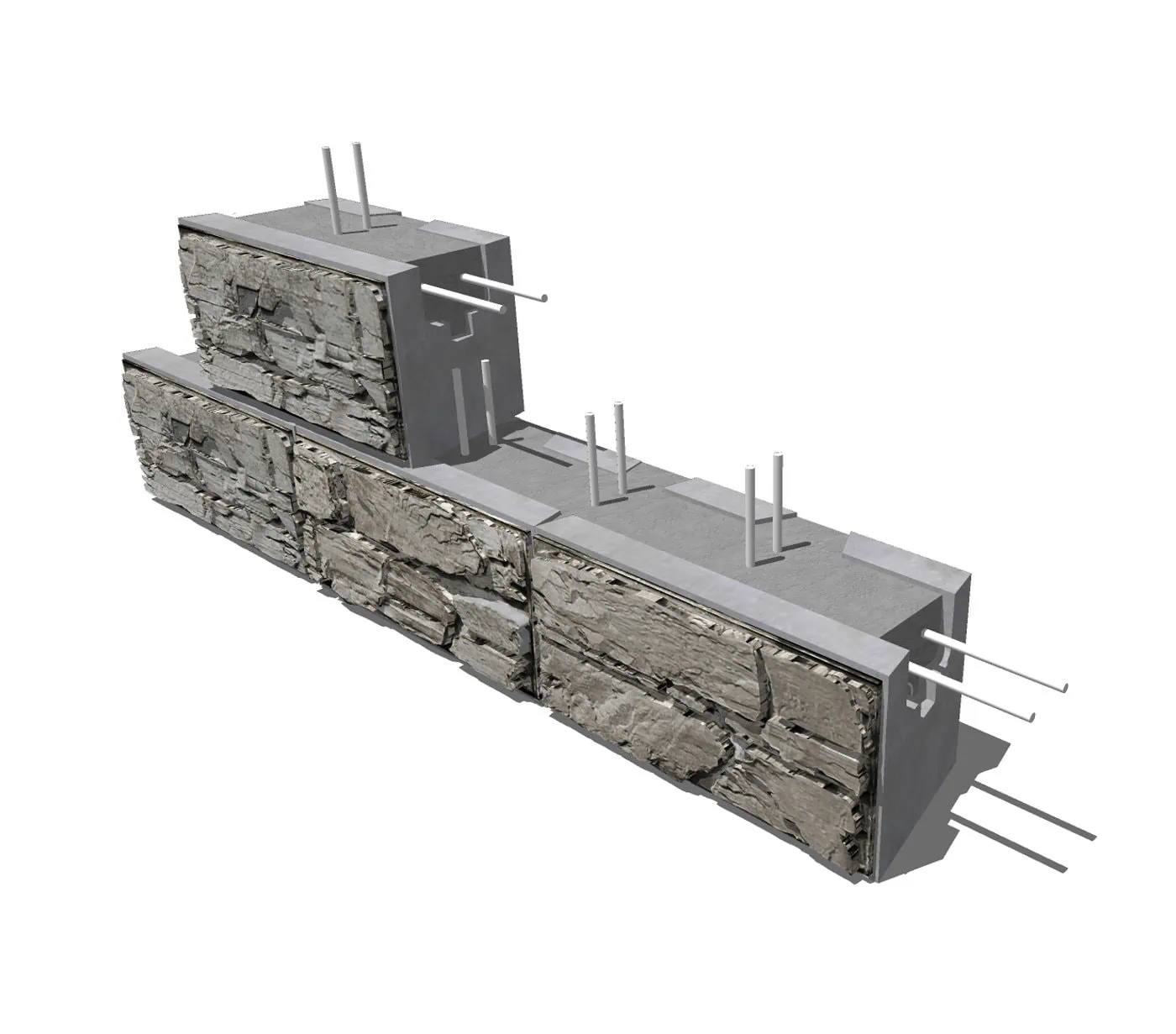

The blocks’ advanced hollow core design makes versatility and drainage a breeze. By filling the core of each unit with crush gravel, the blocks regain a permeable mass that allows water to move freely through built-in lateral and vertical drainage channels. These outstanding drainage capabilities prevent stagnant or pooling water behind the MagnumStone blocks. The value of these drainage details results in sustainable, long-lasting bridge infrastructure built for high-volume traffic.

Coastal Erosion Protection

Rising sea levels and disappearing beaches are telltale signs of gradual coastal erosion around the world. Protective measures like sea walls and reinforced coastal land help preserve structures and shorelines, this is where precast retaining wall systems are in their element.

The effectiveness of hollow core big blocks for water applications have been well-documented here and with a case study here. Furthermore, a blog about concrete retaining wall systems and their advantages for flood and erosion prevention can be found here too.

Erosion management pertains to a wide spectrum of applications, including inland canals or stream banks and the complex, developing necessities of coastal properties. In fact, precast blocks perform extraordinarily well in saltwater conditions. When exposed to salt water, alternatives like steel gabion basket walls corrode and require continuous monitoring and repairs. Precast blocks save on labor thanks to quick installations and also demand minimal, if any, maintenance.

Taller Gravity Wall Solutions

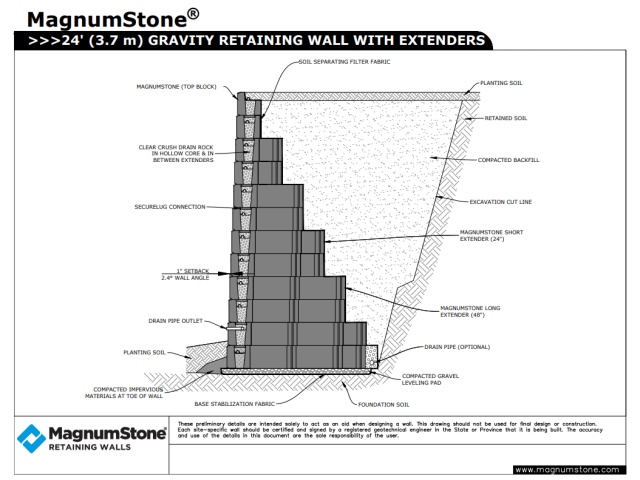

With less and less land to develop, today’s construction is now performed in closer quarters than years past, leading to more strategic retaining wall designs. In order to optimize space and build closer to property lines, the invasiveness of geogrid wall designs is being substituted for the compact footprint of gravity retaining walls. The issue with gravity retaining walls is that most big block systems’ gravity walls are limited to relatively short heights, whereas MagnumStone can built much taller gravity walls.

For greater design flexibility in tight spaces, MagnumStone’s multi-length gravity extender units interlock behind standard blocks to form a greater mass at the base of the wall. The engineered gravity extenders are capable of building taller gravity retaining walls, with excavation area base-to-height ratios as low as 40%. That saves significant real estate when compared to 60% base-to-height ratios for typical geogrid designs.

Save time and budget on future infrastructure projects with less truckload deliveries, quick installations and our comprehensive Retaining Wall Design & Analysis Software. For block pricing and availability, contact your nearest supplier today.

Photos: Cirtex, STI Precast, Midwest Block & Brick, Masters Concrete Products, York Building Products, SLN Contracting & Lee Building Products.