MagnumStone Wing Wall Bridge Designs

The next generation of global infrastructure is on the rise, as private developers and government agencies shift gears to ensure projects are built for long-term sustainability. This includes a full retool of global building materials to proactively construct the future with modern alternatives like MagnumStone’s precast big block retaining wall system. In 2020, there were over 220,000 bridges in the United States deemed to be structurally deficient (report by American Road and Transportation Builders Association, 2021). With hundreds of thousands more worldwide, MagnumStone is helping to accelerate these projects, including bridge wing walls, as a quintessential element to the safety and future economic growth of global communities.

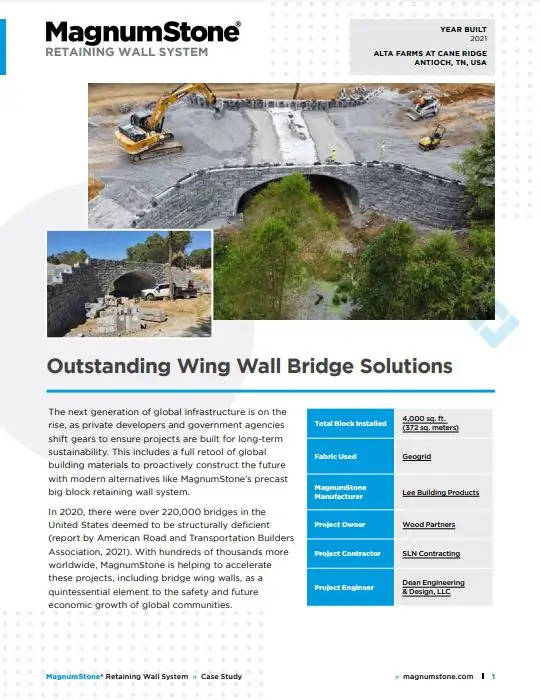

To that point, versatile and innovative retaining walls are in high demand to combat the massive influx of deteriorating infrastructure. Precast big block retaining walls like MagnumStone are up to the challenge, offering modern engineering solutions that can be manufactured and installed efficiently at a swift pace. A prime example is this case study’s bridge abutment project for Alta Farms at Cane Ridge, located in Antioch, Tennessee, USA. This project showcases how MagnumStone precast retaining walls blocks are a viable solution for today’s backlog of infrastructure maintenance and the recent constraints of immense global labor shortages.

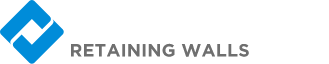

Proudly recognized as the world’s first wet-cast big block hollow core retaining wall system, MagnumStone’s innovative big blocks have become an exemplary building material for future infrastructure projects worldwide. The hollow core block’s ease of installation, proven track record of success and precast resiliency make it an optimal choice for infrastructure and development projects.

Building Bridges with Precast Concrete Retaining Walls

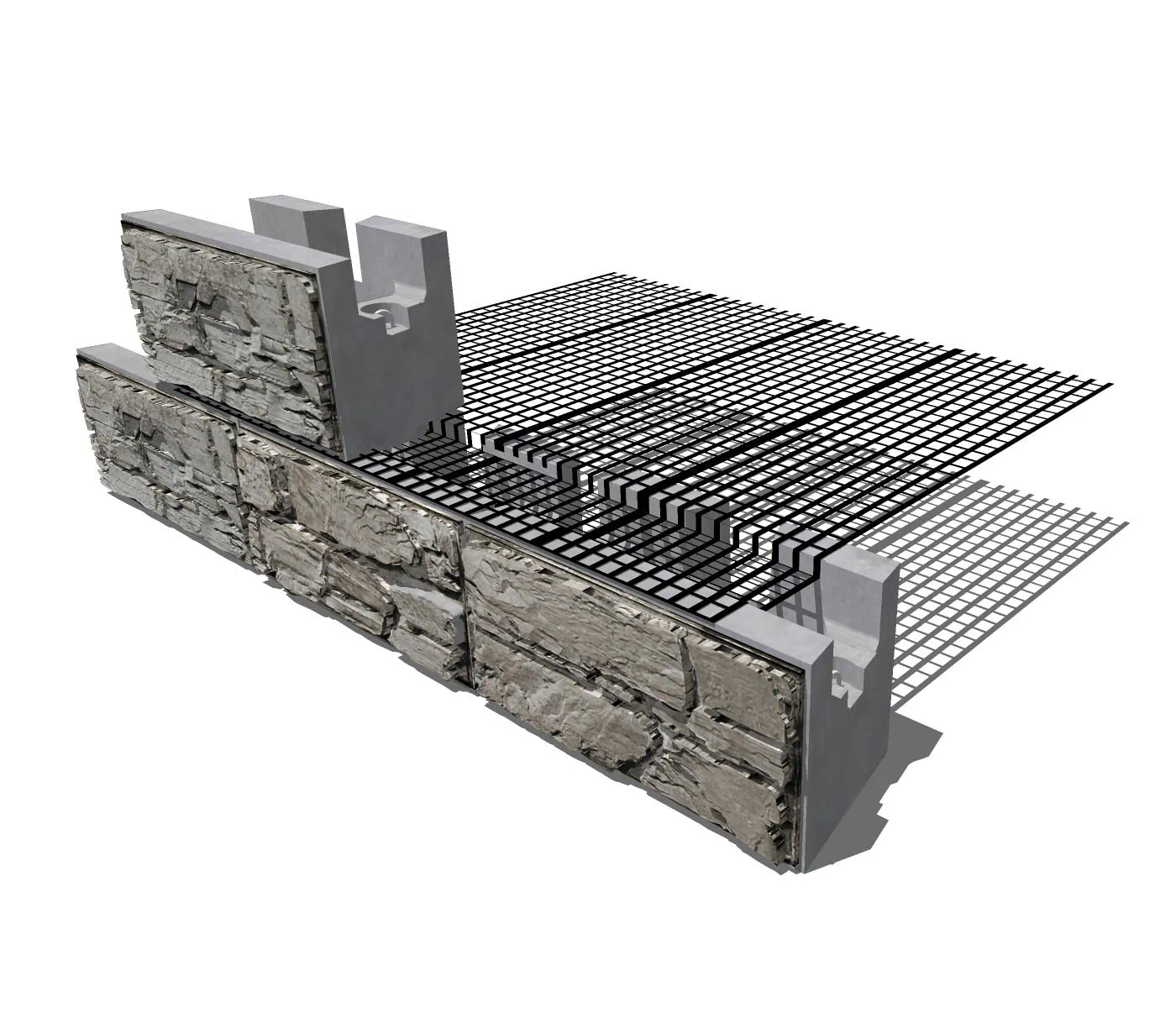

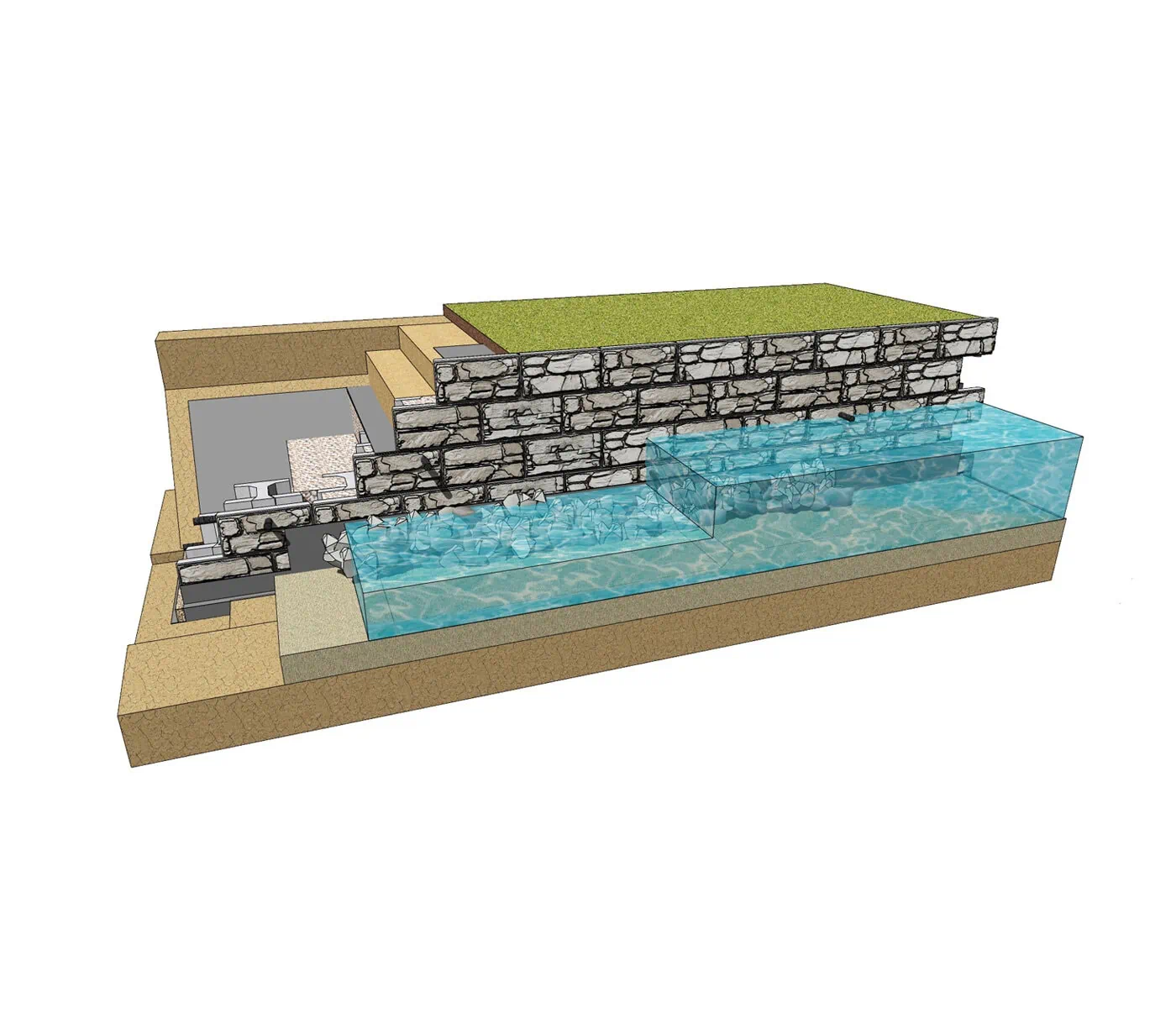

The new Alta Farms at Cane Ridge multi-family development, owned by Wood Partners, hired the experts at SLN Contracting to install a new bridge structure to facilitate an access road over a seasonal waterway. The developers requested a modern looking retaining wall system for wing walls that could flank the bridge’s large culvert and proficiently manage stormwater runoff from a nearby lake.

Dwayne Lowery, owner of SLN Contracting, is equipped with 30 years of expertise installing retaining walls and knew MagnumStone’s precast blocks were a perfect fit for Alta Farms at Cane Ridge. Constructed in 2021, the bridge featured over 4,000 sq. ft. (372 sq. m.) of MagnumStone blocks with a maximum height of 16 ft. (4.88 m.). Lowery selected MagnumStone’s engineered design and handsomely rugged aesthetic thanks to his appreciation for the system’s simplistic installation process and effective stormwater management capabilities.

LEE Building Products owns the closest MagnumStone manufacturing facility to Antioch, Tennessee, located in Bardstown, Kentucky. LEE Building Products has a storied history of producing high-quality concrete products, including MagnumStone, and unwaveringly supplied the retaining wall blocks for Alta Farms at Cane Ridge.

“We anticipate supplying precast blocks for a lot of infrastructure projects similar to this one across the southeast region of the USA, this product offers all of the solutions needed to replace and repair hundreds of bridges in our region,” said Gene Rhodes, Product Sales Specialist of Lee Building Products. “Speed, economics and block availability all play prominent factors in these projects.”

Factoring in the system’s reduced labor and installation time, the SLN Contracting team discovered MagnumStone’s precast concrete blocks would be the most cost-effective retaining wall material. MagnumStone’s cost-effective, machine-powered installation methods even covered the expense of shipping blocks over 130 miles (260 km) to Tennessee rather than installing locally available SRWs.

Efficient Wing Wall Bridge Installations

When installing cast-in-place concrete, multiple teams – including crews for framing, rebar and concrete – must begin and finish their work before next steps can be taken. If any of those teams are delayed, project timelines quickly become derailed. These factors can cause a trickle-down effect that costs taxpayers or landowners more money. MagnumStone’s installation advantages include saving time and costs, with the former contributing to the latter. Another key benefit is that construction sites can be staged in advance to accelerate timelines.

“MagnumStone’s precast retaining wall system is extremely easy to build, our crew can install a full truckload of these blocks in less than an hour,” said Lowery. “We could not have completed this bridge as quick as we did with any other retaining wall product. Installing an SRW system for this project would have taken six people at least six weeks to complete.”

Instead, the bridge was easily installed by only four people in four weeks. If not for logistical delays of a new access road and some weather delays, the retaining walls would have been completed in just three weeks.

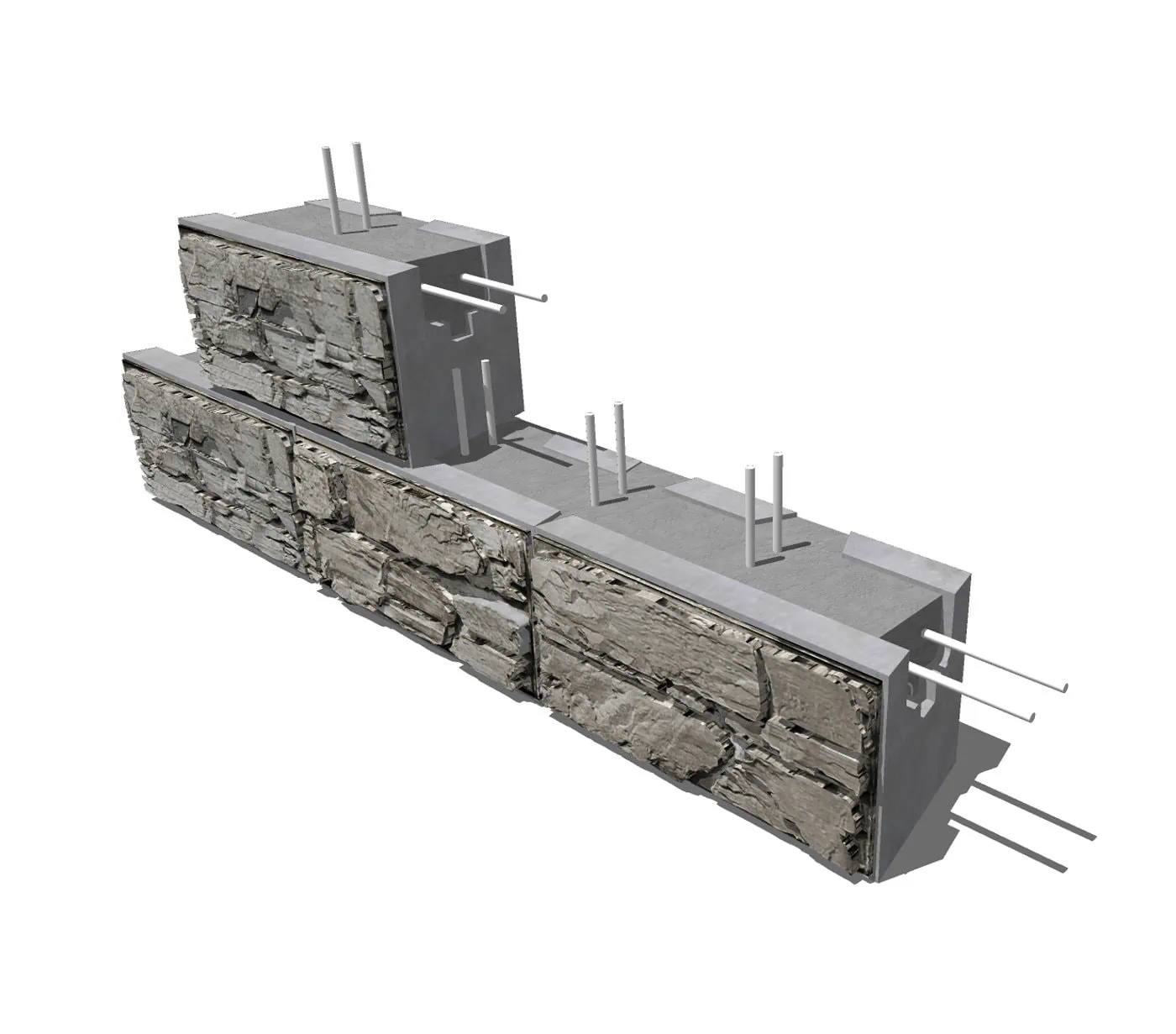

The bridge’s wing walls had to be built together, one course at a time and measured daily to ensure the culvert’s positioning and structural integrity remained uncompromised. MagnumStone’s ease of installation was pivotal maintaining equal pressures on each side of the culvert throughout construction. SLN Contracting credited MagnumStone reliably quick installation process for this project’s success.

MagnumStone blocks use 40% less concrete than solid concrete systems, helping keep projects on track by effortlessly moving blocks with hydraulic equipment including skid steers and small excavators. Each standard block covers a total of 8 sq. ft. (0.74 sq. m.) to maximize efficiency. With global workforce shortages, this automation helps eliminate project management complications.

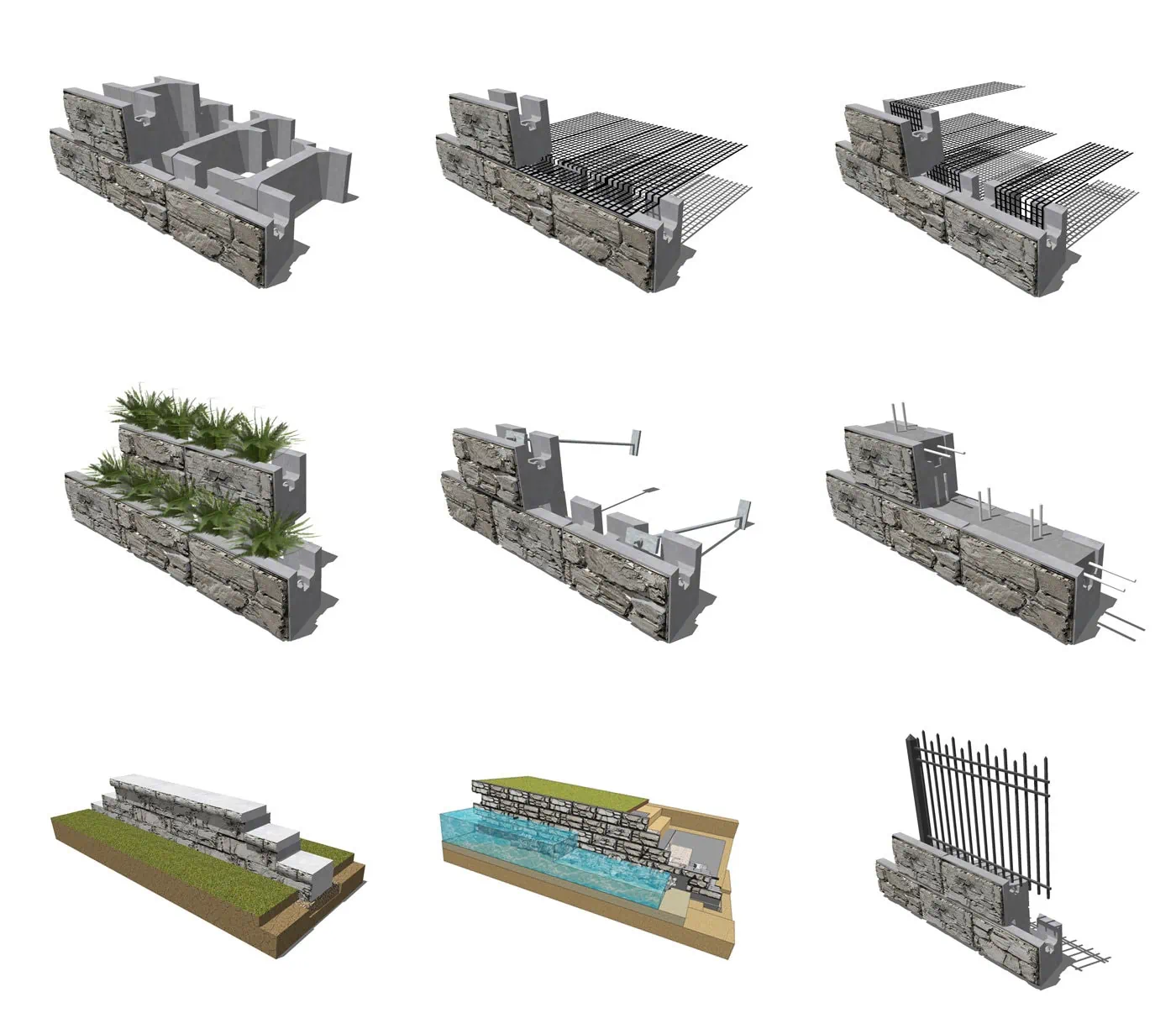

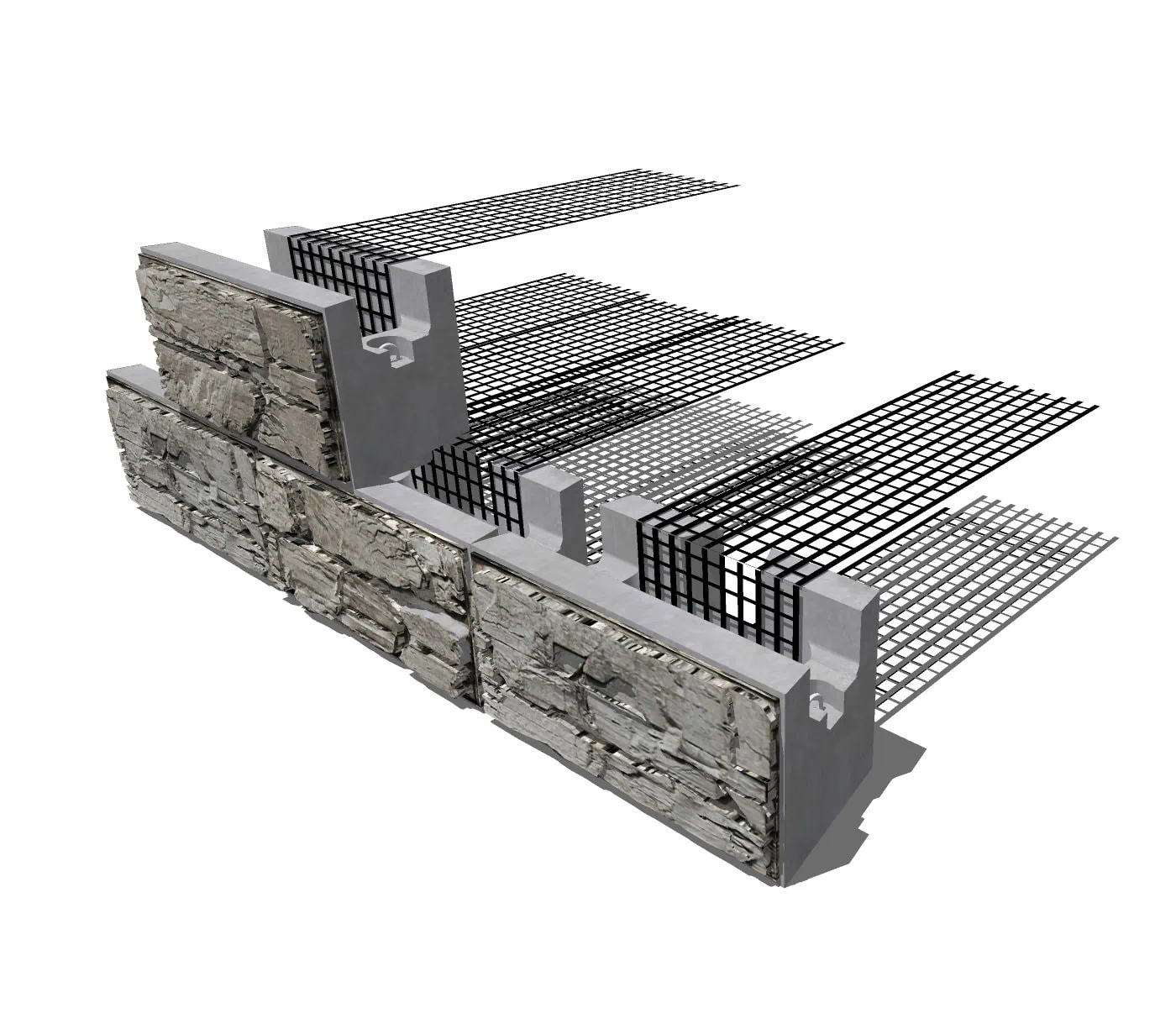

Achieve 100% Geogrid Coverage

The new bridge for Alta Farms at Cane Ridge is a positive connection design to accommodate heavy loads of the development’s construction equipment and large vehicles. With this design, the bridge meets Tennessee’s Department of Transportation (DOT) codes and aligns with Federal Highway Administration (FWHA) standards. Thanks to its weather-resistant precast blocks, MagnumStone excels in any retaining wall application, no matter the project size or complexity.

Trenton Smith of Dean Engineering & Design, LLC, in Knoxville, TN, was the Project Engineer and used MagnumStone’s free online Retaining Wall Design & Analysis Software to ensure the design was structurally sound. MagnumStone’s precast hollow core block design allows for geogrid to pass through the top of the block and underneath. Combined with the retaining wall system’s running bond pattern, this provides 100% coverage of geogrid material above and below each course of the bridge wing walls for maximum reinforcement and stability.

“By delivering 100% coverage for positive connection retaining wall designs, MagnumStone makes it easy to design with lesser strength geogrid,” said Smith. “Saving costs on unnecessary high-strength geogrid goes a long way. MagnumStone’s big blocks work great for reinforced walls, its block height of 2 ft. (0.61 m.) is truly a sweet spot for retaining wall design.”

The precast block’s defined, built-in drainage column at the front of the blocks also makes drainpipe planning easy to facilitate. Therefore, the hollow core’s vertical and horizontal drainage channels can easily adapt to fluctuating water levels of the stream below. This protects the newly built infrastructure and prevents future scour and erosion due to stormwater runoff from the lake upstream.

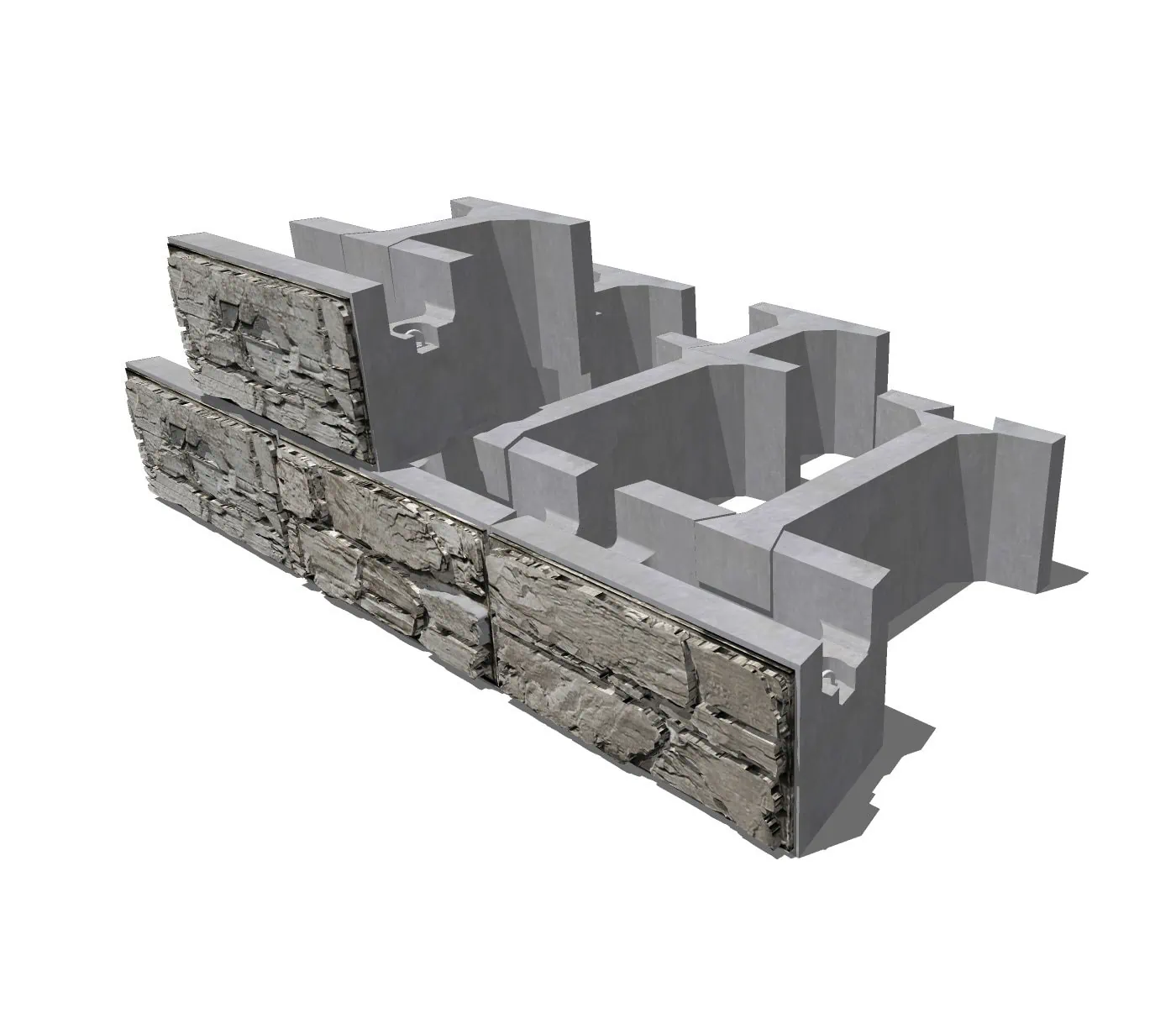

Natural Aesthetics for Future Bridge Projects

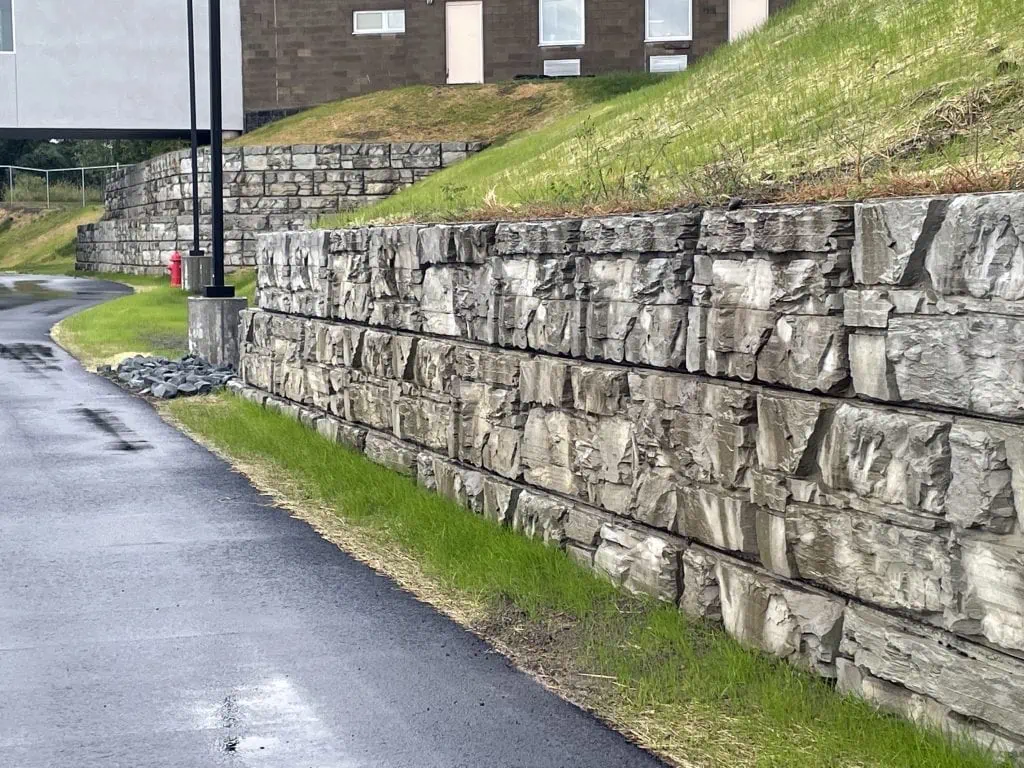

Precast retaining wall blocks’ stellar durability and performance provide infinite reasons to select them for infrastructure and development projects. Appearance does play a role, however. For landowners, engineers and contractors, their hard work always feels more meaningful when projects look amazing. Thanks to MagnumStone’s precast forms, each block face’s natural looks blend into any landscape.

“No other brand of retaining wall matches the aesthetics of MagnumStone blocks,” notes Lowery. “Everything about the block is perfect, from its engineered design, beautiful looks – and it even eliminates the immense physical toll that lifting blocks day after day takes on our installation team.”

It’s for that reason that the developers preferred MagnumStone’s gorgeously textured look, which gives the bridge a timeless, rocky aesthetic. The system’s precast form facings are forged from craggy outcrops of the Canadian Rockies which can infuse any infrastructure project with an element of authentic, natural beauty.

Streamlining Wing Wall Bridge Construction

These modern bridge wing walls for Alta Farms at Cane Ridge are a prime example of how infrastructure projects across the world can be dealt with in effective, efficient ways. Precast big block retaining walls like MagnumStone reduce exorbitant costs of supplementary materials and unnecessary project delays, two prominent factors which drastically complicate infrastructure projects.

The future of global infrastructure depends on streamlined processes, automation and innovative building materials. With less and less usable land to develop and design considerations like stormwater management becoming such a vital component of infrastructure, the durability of precast big blocks like MagnumStone will soon be in demand more than ever.

Hundreds of thousands of crucial bridge and culvert wing walls similar to Alta Farms at Cane Ridge will require repairs or full rebuilds over the coming years and decades. This project further proves that precast big block retaining walls will provide safe and financially sound solutions to maintain, advance and expedite the future of global infrastructure.

MagnumStone offers protected, licensed territories to manufacture precast retaining wall blocks with the best engineering support, software and products available on the market. Contact the experts at MagnumStone for more details about licensing opportunities near you.

Project Photos: Dwayne Lowery, SLN Contracting.