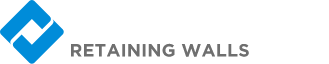

Retaining walls, embodied in a wide variety of shapes and sizes, each cater to a unique set of project requirements. However, the construction industry has seen a shift. A shift towards the use of substantial concrete blocks, with MagnumStone’s advanced system leading the revolution.

This system simplifies the installation process. It also introduces key benefits that make construction projects more efficient. A critical function of retaining walls lies in their robust tensile strength. This makes them have long-lasting durability. They reinforce, stabilize, and safeguard your property, often enhancing its value in the process.

Now, let’s delve into why precast modular block (PMB) concrete systems are carving out a niche as the industry standard globally.

1. Fast, Efficient Retaining Wall Installations

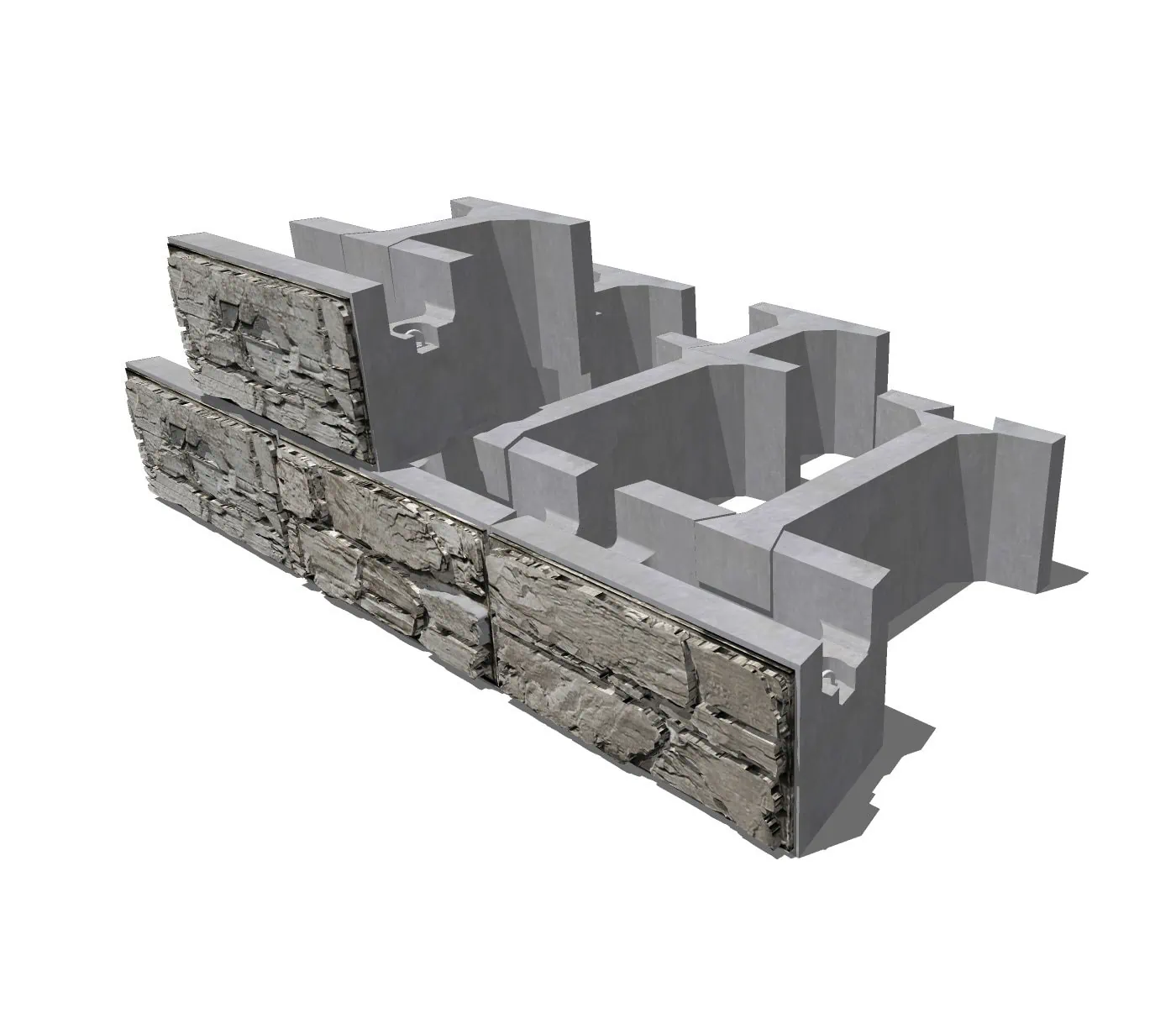

Effectively managing resources is critical to any retaining wall project to ensure you stay on schedule and within budget. Unlike SRW systems, MagnumStone’s PMB units cover 8 sq. ft. (0.74 sq. m) of wall facing per block. Larger units come together quicker and can save significant labor expenses associated with building your retaining wall.

Contractors worldwide prefer using MagnumStone because the blocks are designed for simple, cost-efficient installations. Professional three-person crews can easily make quick work of projects by installing over 1,000 sq. ft. (93 sq. m) per day!

2. Build More with Smaller Equipment

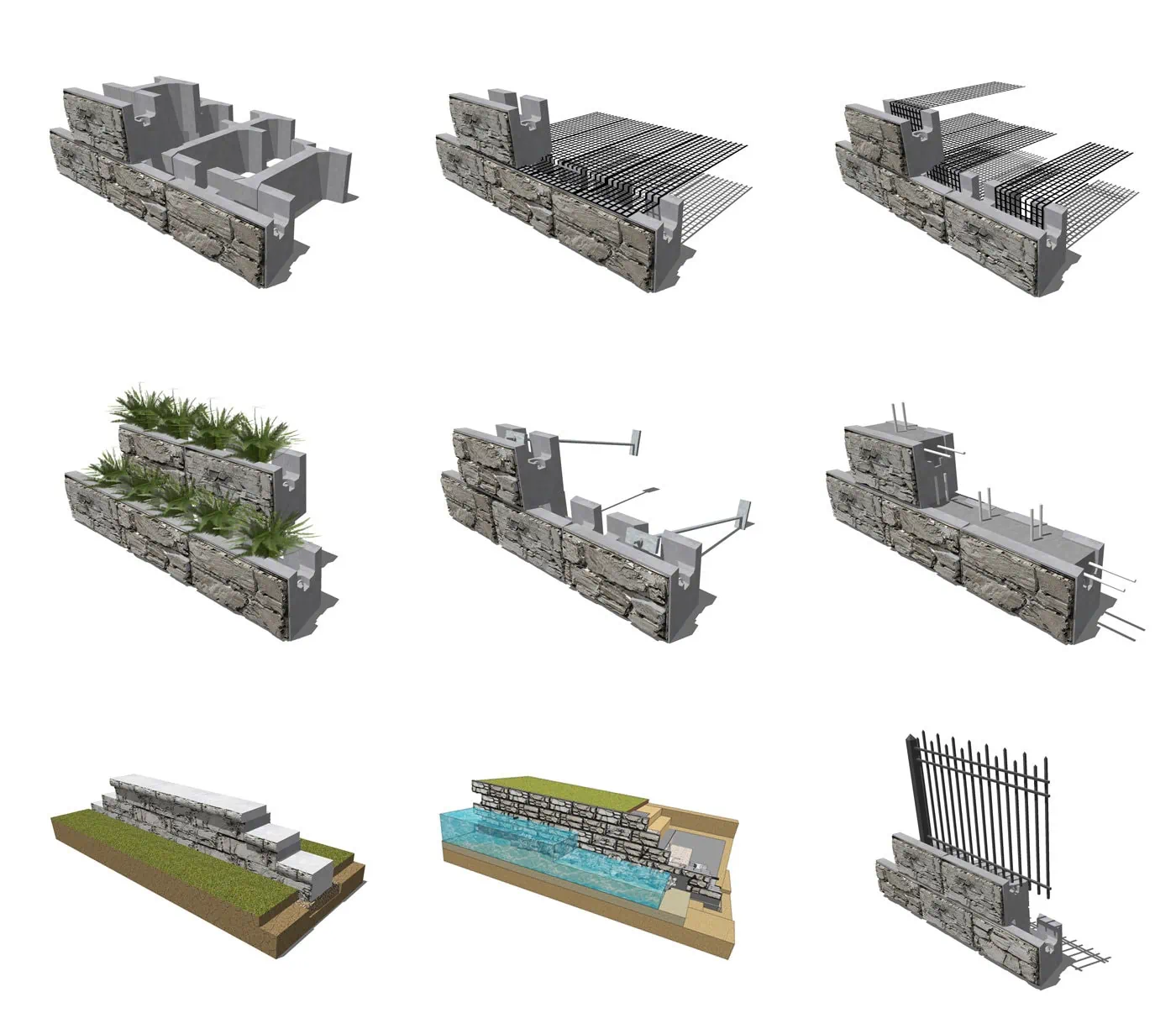

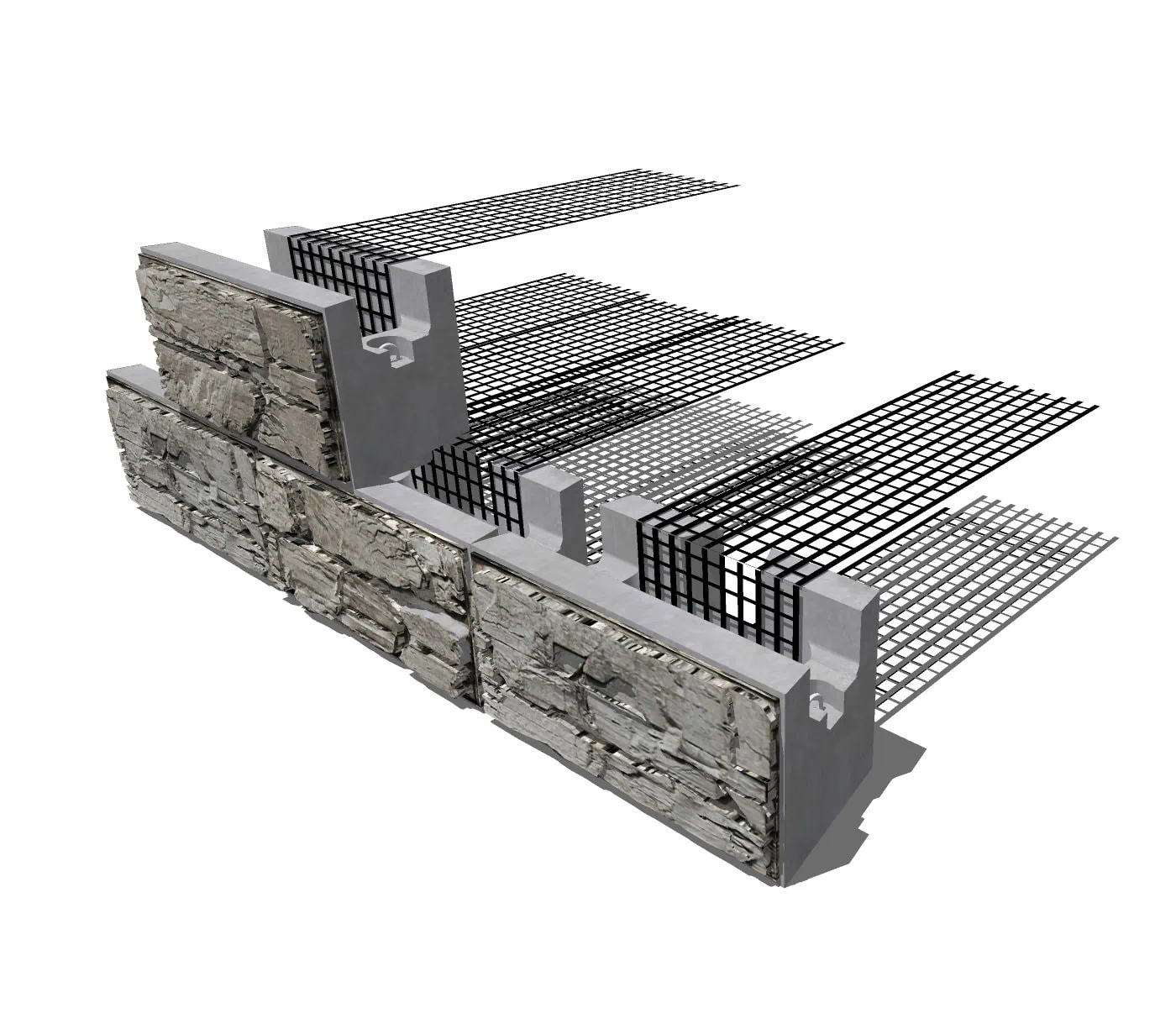

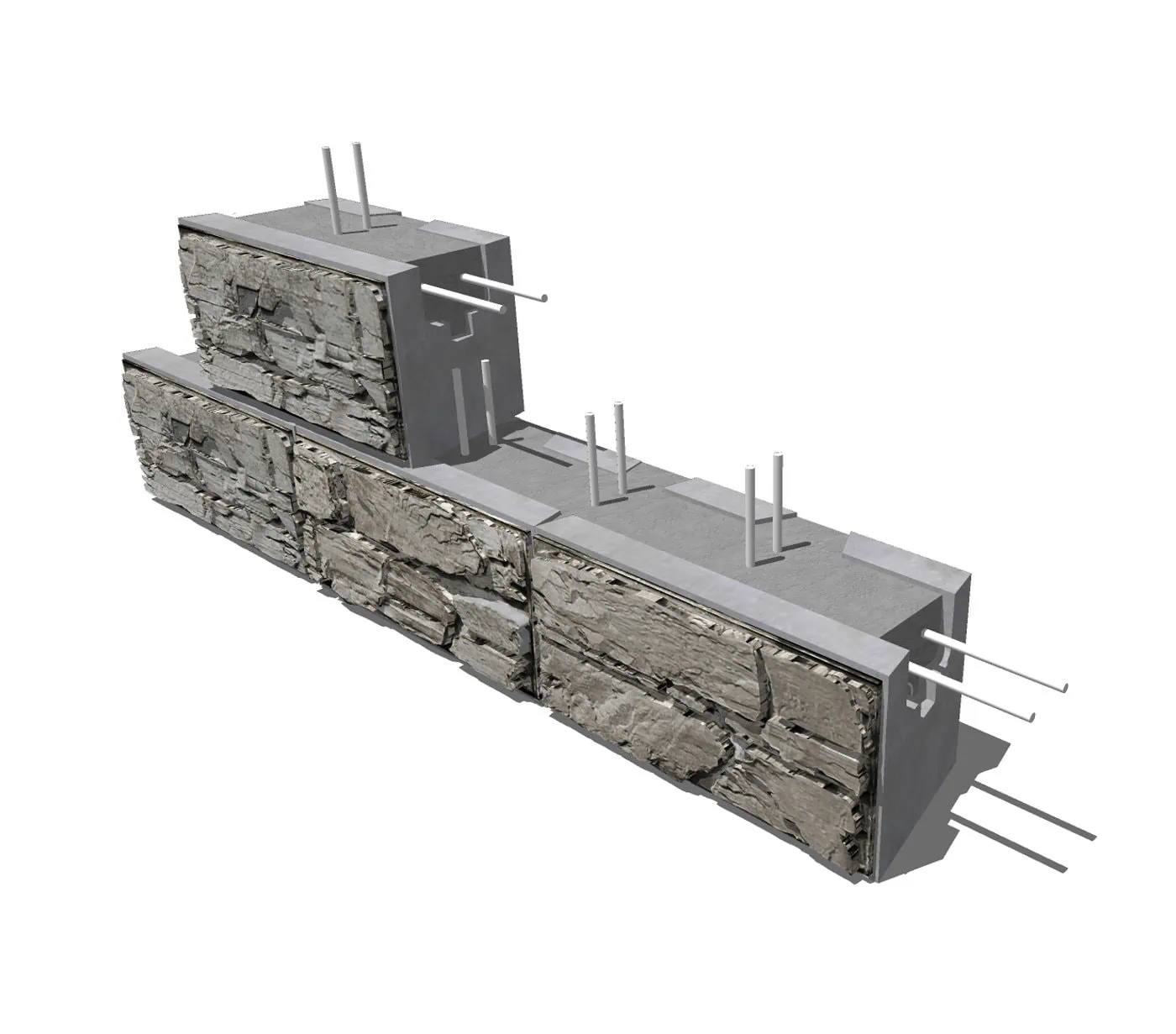

Why spend money on unnecessarily large excavators when the job can be done with smaller, more affordable equipment? Compared to solid concrete systems, MagnumStone’s hollow core block design uses 40% less concrete, making each standard block up to 40% lighter than alternative systems. This makes it more compatible with different equipment so that unnecessarily large, oversized equipment isn’t required.

Fun fact: A standard Bobcat can lift two MagnumStone blocks at once (16 sq. ft. / 1.5 sq. m.!), which will make any contractor happy.

3. Durable Longevity of Wet-Cast Concrete

Alright, so the case has been made for cost efficiency, but are big block retaining walls built to last? Precast wet-cast retaining walls are manufactured with consistency and strength top of mind.

Wet cast concrete production results in minimal water absorption. It also results in a dramatic increase in weatherproofing. MagnumStone manufacturers worldwide have a minimum requirement of 4,000 PSI (24MPa) strength mix design. This is to ensure uncompromised durability that withstands the elements.

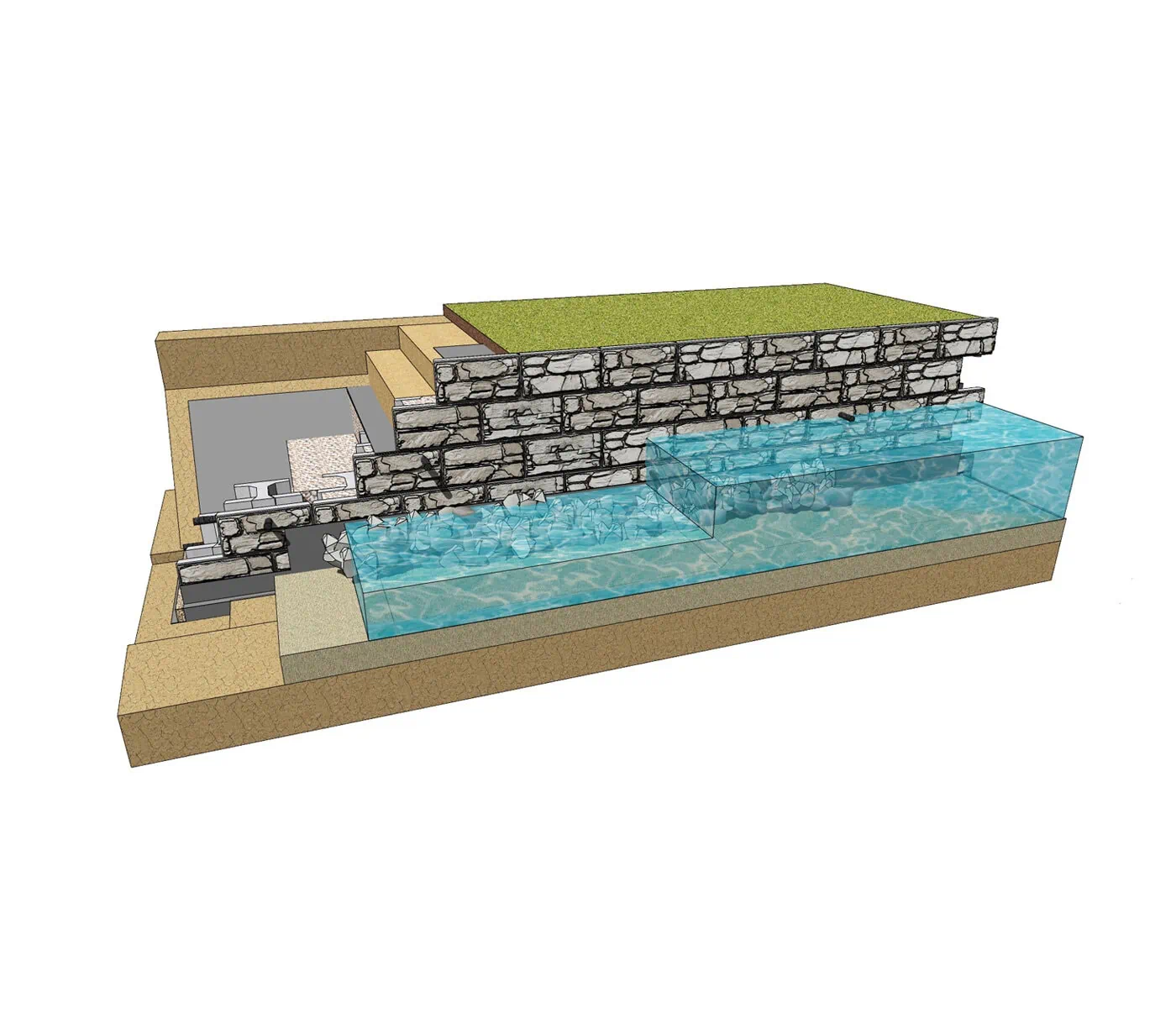

MagnumStone big blocks are battle-tested as durable oceanfront retaining walls and stormwater management systems. They’re also approved by several Departments of Transportation. Want to learn more? Check out our case studies to discover how effective MagnumStone walls are.

4. Eco-Friendly Big Block Retaining Walls

Did you know large retaining walls can be environmentally friendly as well? MagnumStone’s hollow core design uses 40% less concrete (and far less water) to manufacture than solid concrete systems. This allows us to ship more units per truckload and use smaller equipment on-site. It also reduced CO₂ emissions throughout the process. More blocks, less truckloads. A win-win situation.

Plus, the hollow cores can be used for more creative projects like Plantable Walls. Plantable Walls further reduce heat island effects which harm our environment. This is done by minimizing concrete usage and promoting more green space.

5. Build Beautiful Precast Modular Block Retaining Walls

The look of retaining walls has come a long way over the past few decades. Modern natural stone facings provide fresh, professional aesthetics that everyone loves. From gabion-style structures and flat-faced concrete walls. MagnumStone’s craggy, rugged facing blends in with nature and gives properties a stylish touch. This adaptable appearance will stand out to everyone. From designers and installers to homeowners and passersby.

Make your retaining wall projects worthwhile structures you can be proud of.

6. Less Excavation Area, More Space to Play

MagnumStone’s one-of-a-kind gravity extenders need less excavation area for retaining wall projects. With these, MagnumStone’s big blocks can fit in tight urban centers for infrastructure development. It also creates elegant, spacious backyard spaces.

Are you intrigued by the potential of MagnumStone precast modular blocks? Would you like to explore how they can contribute to the extension, security, and strength of your property? There’s no better time than now to delve into the vast possibilities that these advanced retaining wall blocks offer.

Discover how MagnumStone precast modular blocks can extend, secure and strengthen your property today by visiting MagnumStone Retaining Wall Solutions & Designs or contacting your nearest MagnumStone supplier.

Photos: Cirtex, Masters Concrete Products, Barkman Concrete, TJR Concrete, Oberfields LLC and York Building Products.