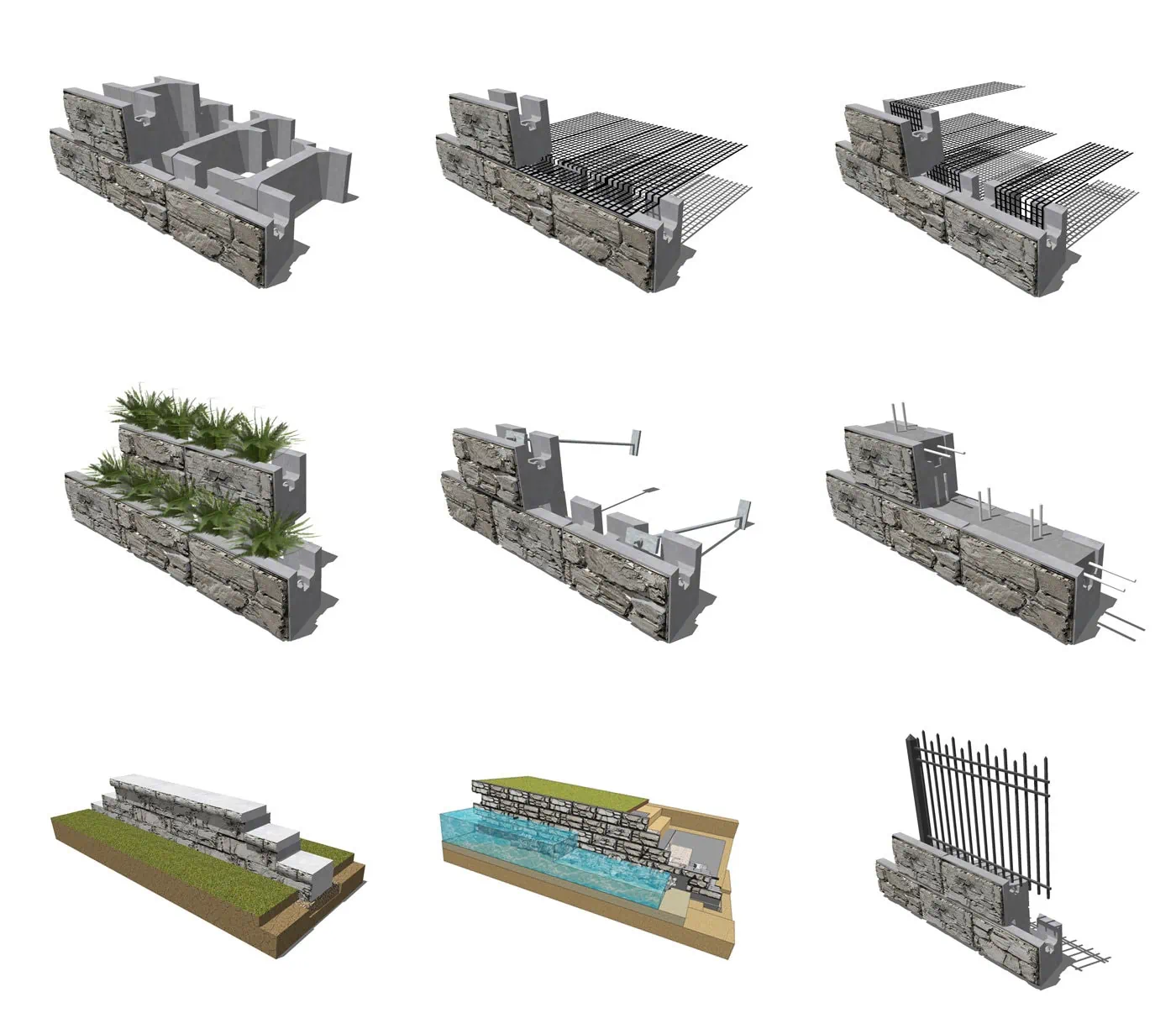

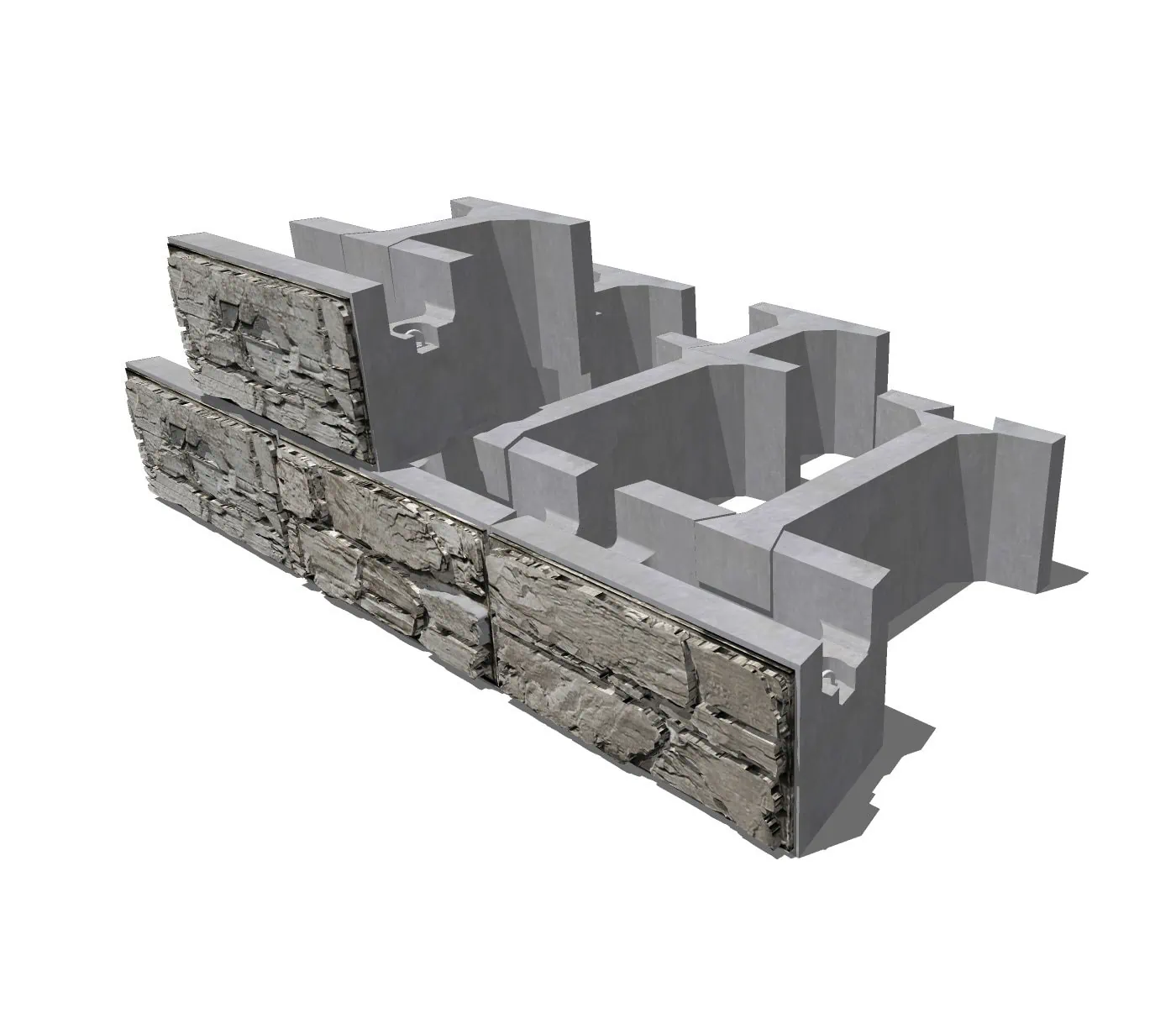

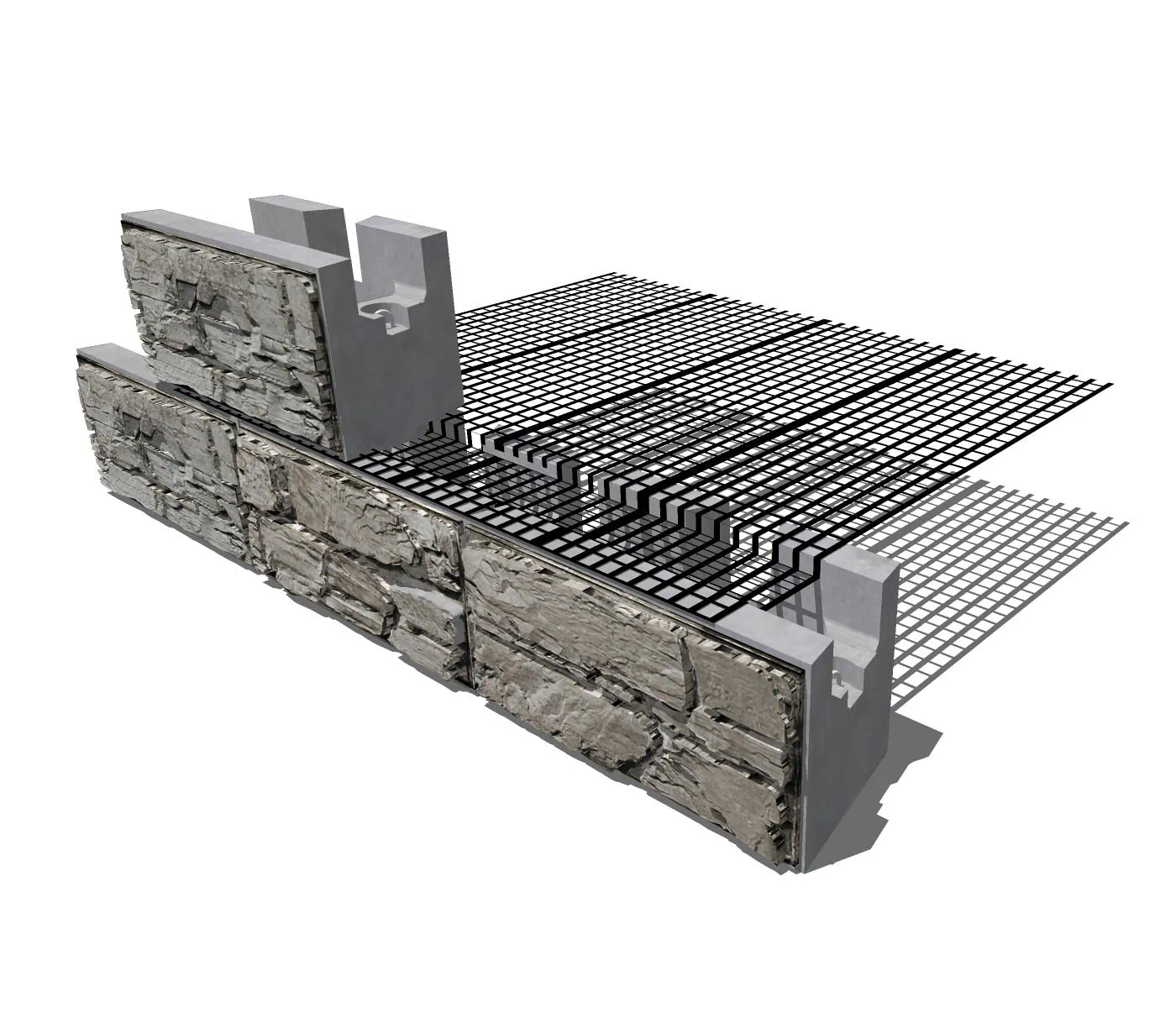

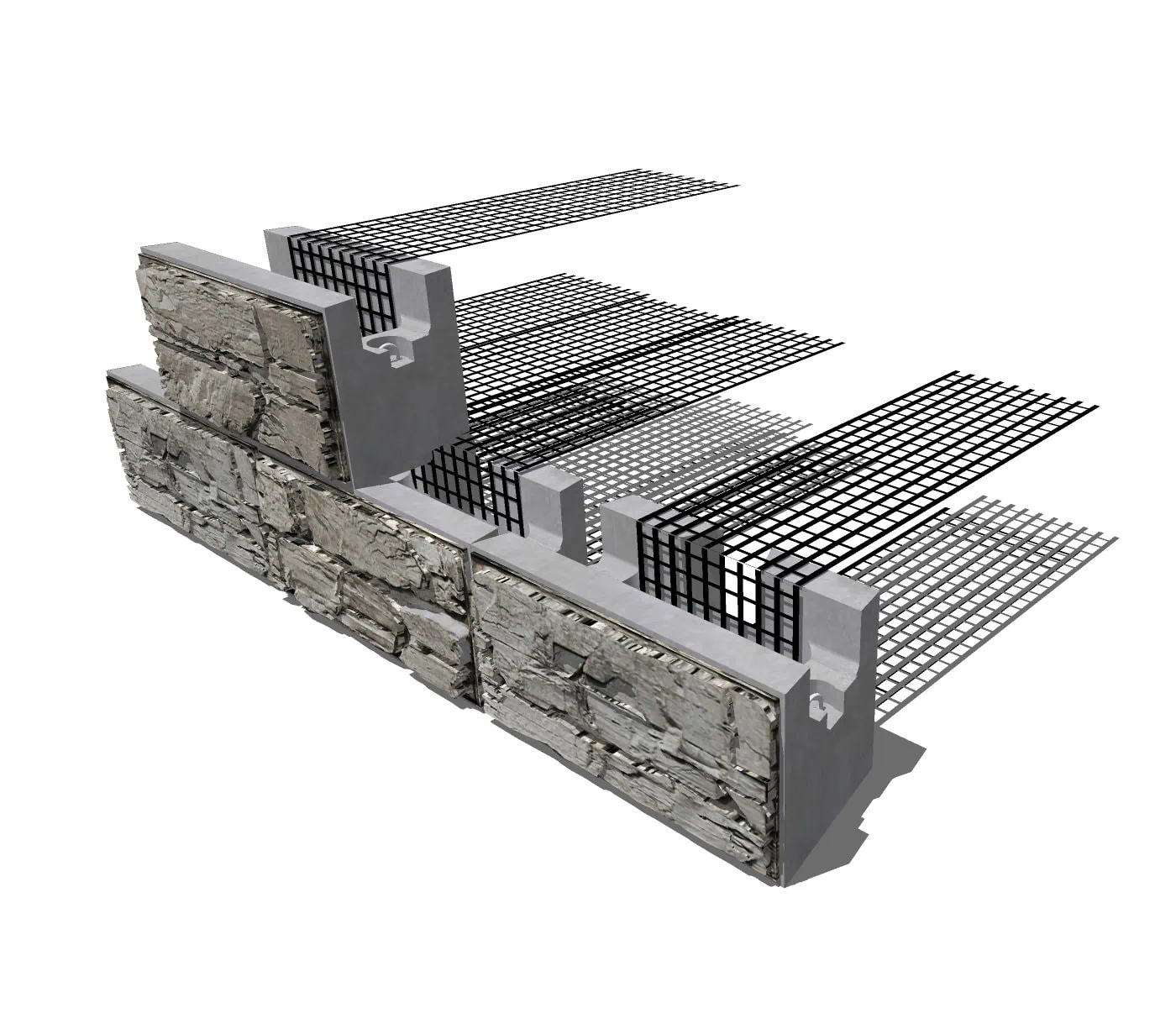

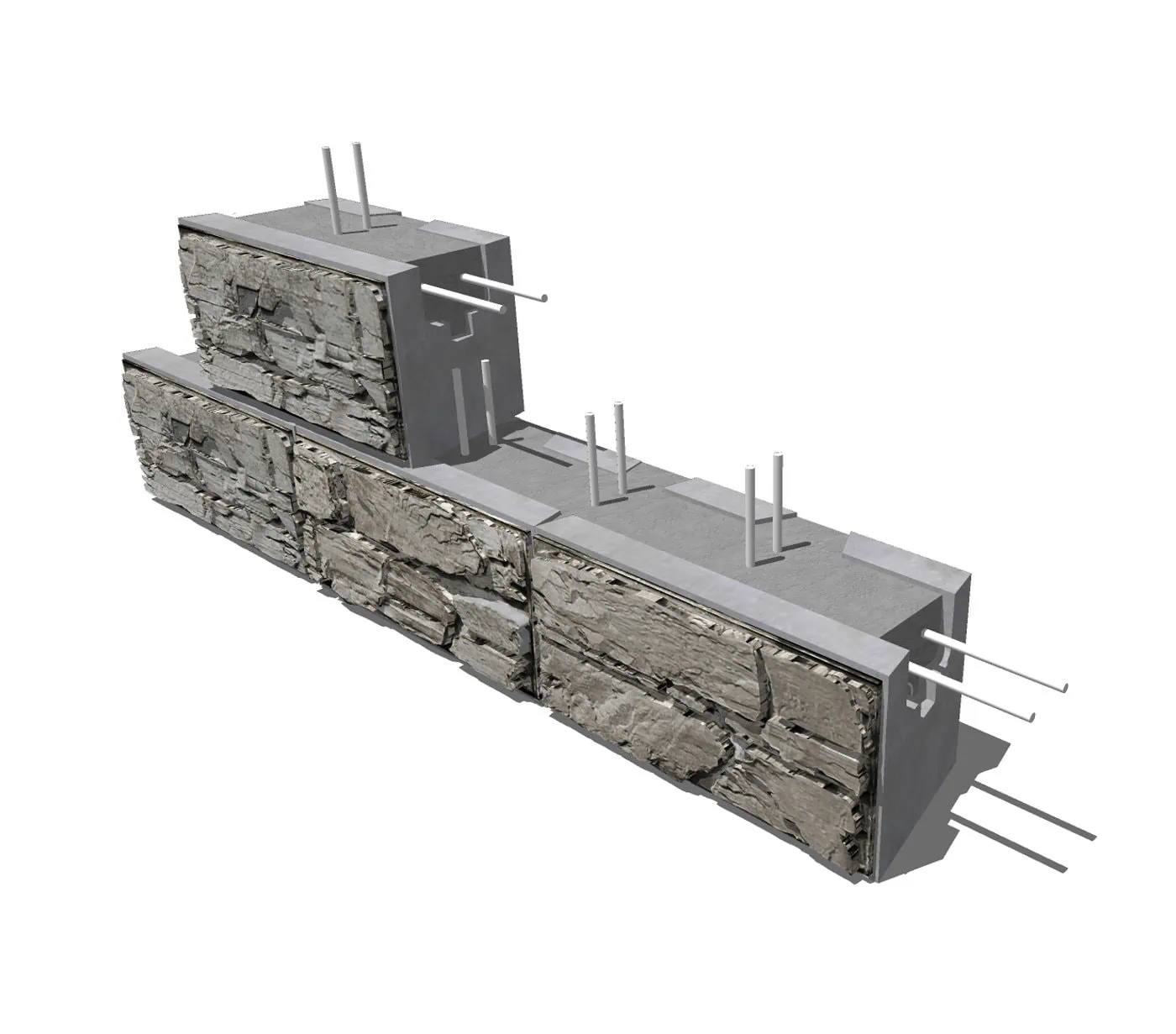

MagnumStone Retaining Wall Units are large wet-cast concrete units with a horizontal and vertical hollow core. The open core make the units easier to ship and handle in the field and allows for vertical internal drainage, minimizing the effects of hydrostatic pressures behind the walls and facilitates design options for ‘rapid draw-down’ in the case of flooding. Wet-cast MagnumStone units provides a durable, 4000 psi (27.5 MPa) concrete that is resistant to freeze-thaw degradation in areas of repeated freezing and thawing in saturated conditions. Designing for water conditions requires the designer to investigate several design options.

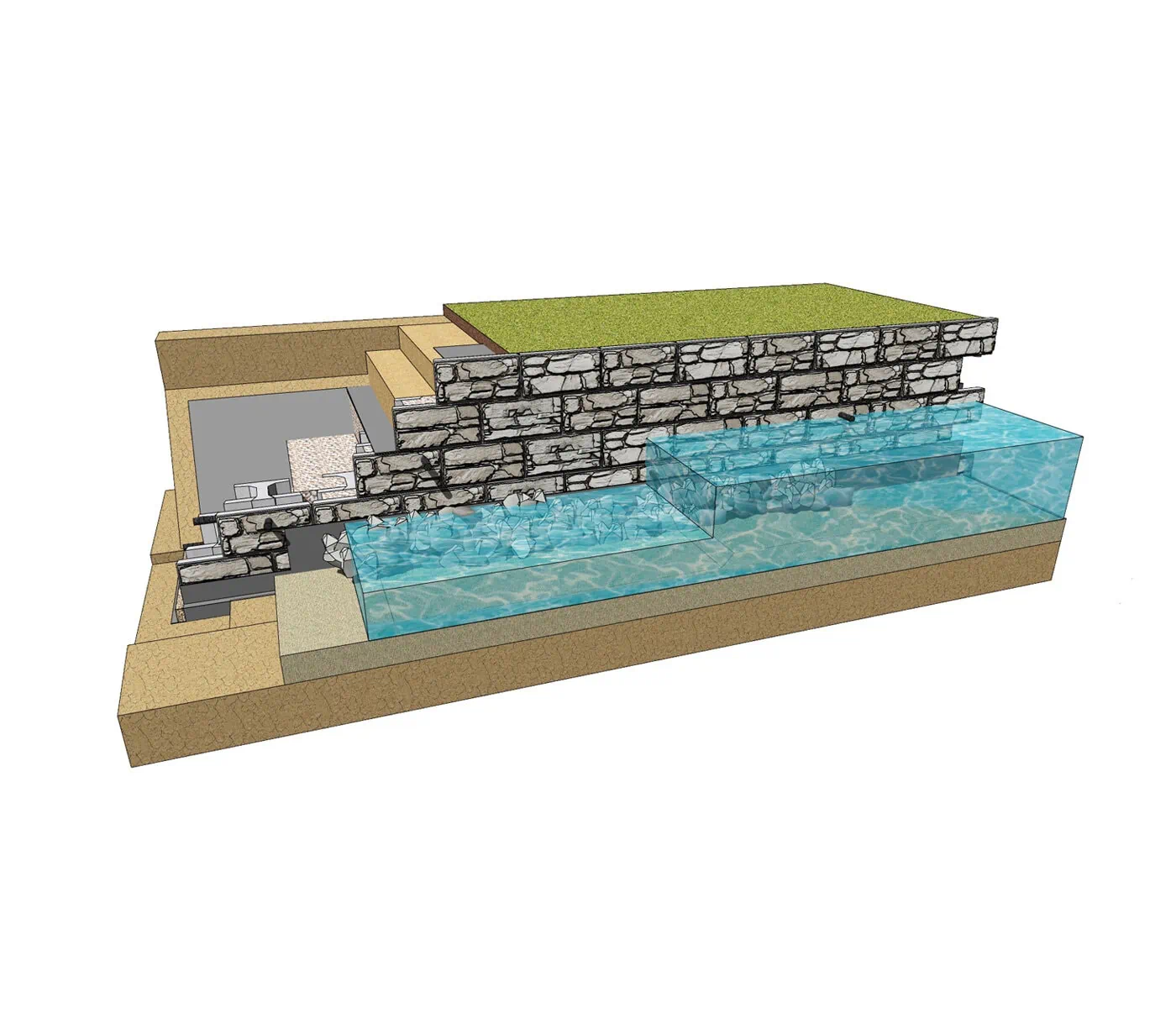

Channel Liners / Channel Flow

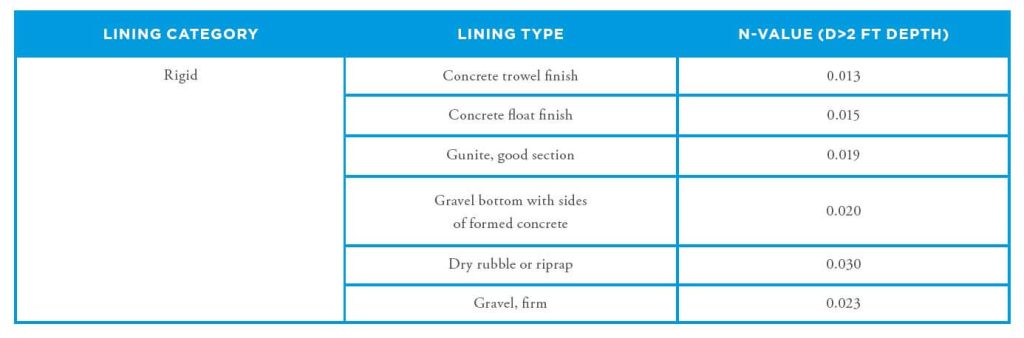

MagnumStone units are often used as sidewalls for drainage channels. In flowing conditions the roughness of the block and the Manning’s N value are important to flow conditions.

V =1.49?n r^(2/3) s^(1/2)

Where: V = velocity (fps)

n = Manning roughness coefficient

r = hydraulic radius (area / wetted perimeter)

s = slope of channel

[REF. Engineering Field Handbook, H-210-NEH-Part 650-Engineering Field Handbook, USDA National Resources Conservation Service, Jan 2012.]

Table 1: Chow, Open-channel Hydraulics. McGraw Hill, NY, (1959) pp. 262-267

Based on the finished concrete surface and the textured surfaces, a manning’s n value of 0.015 is recommended.

Embedment

Flow in the channel is based on stream bed slope (s) and roughness of the base and side walls, and can be determined using the manning equation shown above. The long-term performance of the channel is based on the stability of the section and the potential of the flow to undermine (scour) the base below the MagnumStone units.

The AASHTO Bridge Manual suggests a minimum embedment depth of 2.0 ft [REF. AASHTO LRFD Bridge Design Specifications, American Association of State Highway and Transportation Officials, v6, 2012.] below potential scour depth.

Durability

Concrete products that are saturated and subjected to repeated freezing and thawing are subject to freeze-thaw degradation due to expanding of ice crystals within the concrete matrix. Research has shown a higher tensile strength is required and air entrainment provides for good, long-term performance. Recommendations from the local transportation agencies for a durable concrete mix is recommended. Typical recommendations for concrete would be a minimum compressive strength of 4,500 psi (27.5 MPa) and 6 percent air-entrainment (+/- 1.5%) [REF. ACI-318, Building Code Requirements for Structural Concrete (ACI 318-02) and Commentary (ACI 318R-02), American Concrete Institute, 2002.]

Ice Pressures

Frost Depth

As water freezes it expands causing the freeze-thaw durability issues mentioned above and causing frost heave. Frost action (heave) in the soil is the freezing of moisture in lenses in the soil causing a vertical expansion of the soil. For rigid concrete walls it is recommended the base of the wall be located below frost depth. Because the MagnumStone units are not grouted and the walls are flexible, embedment below frost depth is not required. A minimum embedment of 1.0 ft is recommended in freezing areas, or as required for bearing requirements.

Internal Water

Walls that are located in free standing water may have the water within the units freeze. The water within the units are within a matrix of the gravel fill with a void ratio of roughly 40% (or about 28% water). Because the water in not confined, the water will expand upward within the unit, not causing structural damage to the unit.

Ice Pressure

Walls located in lakes or along rivers may be exposed to pressures from ice sheets during spring break up. It is suggested riprap be placed in front of the walls to deflect the ice upward as in pushes into the wall area and the assist in breaking up the ice sheets.